Engine Manufacturers’ Efficient Efforts for Greener Skies

From structural experiments to efficient propulsion systems, from collaborations to investments and testing, initiatives are underway in a wide expanse

Sustainability is no longer just the buzz word of the town in the aviation industry as there are conscious discussions and actions being taken up constantly. There is a clear awareness that the future of the market will be significantly determined by how the aviation industry innovates to lower emissions and improves fuel efficiency. From airlines to aircraft and engine operators, everyone is playing a key role. Here we take a look at some of the initiatives that the major engine manufacturers have taken to contribute towards greener skies.

PRATT & WHITNEY

As one of the leading names in the engine industry, Pratt & Whitney (P&W) is constantly adding to the list of its sustainable efforts. Developing hybrid-electric propulsion technology is a core element of Pratt & Whitney’s strategy to make aviation more sustainable. The latest being its hybridelectric propulsion technology that aims to drive significant improvements in aircraft efficiency by optimising performance across the different phases of flight, allowing the demonstrator to target a 30 per cent reduction in fuel burn and CO2 emissions, compared to a modern regional turboprop airliner. P&W Canada (P&WC) is working with De Havilland Aircraft of Canada Limited to integrate this hybrid-electric technology into a De Havilland Canada Dash 8-100 flight demonstrator. This demonstrator will include an advanced electric motor and controller from Collins Aerospace, also a Raytheon Technologies business.

Additionally, as part of Canada’s green recovery plan, the Government of Canada’s Strategic Innovation Fund is backing the technology demonstrator. The Government of Quebec is supporting this project through Investissement Québec and the Ministère de l’économie et de l’Innovation, as part of an initiative known as, “Aéronef pour la mobilité numérique et verte de demain” (Green and Digital Aircraft of Tomorrow). P&WC is targeting ground testing in 2022, leading to flight testing of the Dash 8-100 demonstrator in 2024.

P&W Canada (P&WC) is working with De Havilland Aircraft of Canada Limited to integrate this hybrid-electric technology into a De Havilland Canada Dash 8-100 flight demonstrator

The company is also committed to continually advancing the efficiency of gas turbine engines across its portfolio, while supporting the wider use of SAF, and pursuing alternative fuels.

P&W highlighted the following ways in which it’s working to ensure cleaner skies are on the horizon:

- Saving fuel and CO2 with the GTF: Since entering service in 2016, the Pratt & Whitney GTF engine family has made air travel significantly more sustainable. These revolutionary geared turbofan engines deliver 16 per cent lower fuel consumption and carbon emissions compared to previousgeneration engines. GTF engines have already saved airlines more than 470 million gallons of fuel and more than 4.3 million metric tonnes of CO2. With more than 960 GTF-powered aircraft delivered, and another 5,000 on order, P&W’s GTF is a key enabler for airlines to reduce their environmental footprint while still growing their passenger numbers and route networks.

- Investing in Next-gen Technologies: P&W is continually investing in next-generation technologies like electric, hybrid electric and hydrogen-powered propulsion. Active work is going on with hybrid-electric concepts that would address aircraft from regional turboprops to large commercial aircraft. P&W plans to test this technology in flight in partnership with NASA and other public funding bodies. Much like a hybrid car, hybrid electric jet engines will optimise performance across the different usage phases of flight, providing an electric power boost at takeoff and leaving the gas turbine to run at peak efficiency during cruise.

- Advancing use of SAF: All the current engines of P&W are ready to accept the certified maximum blend of 50 per cent SAF with conventional jet fuel. Additional testing and certification work is in the pipeline to approve SAF blends as a 100 per cent fuel replacement.

- Offering a Carbon Offset Service for Business Jet Operators: P&W had launched a Carbon Offset Service for business jet operators, the first service of its kind offered by an engine maker. Available to business jet operators with engines enrolled in P&W’s pay-per-hour Eagle Service Plan (ESP), the Service makes it simple to offset for emissions based on the engine’s flight hours.

- Committing to Reduce our Own Energy Usage, Water Consumption and Waste: P&W has committed to reduce its greenhouse gas emissions by 10 per cent by 2025 (compared to 2019). The company is also working on enhancing sustainability in other aspects like water & waste management, solar energy utilisation, etc.

GE AVIATION

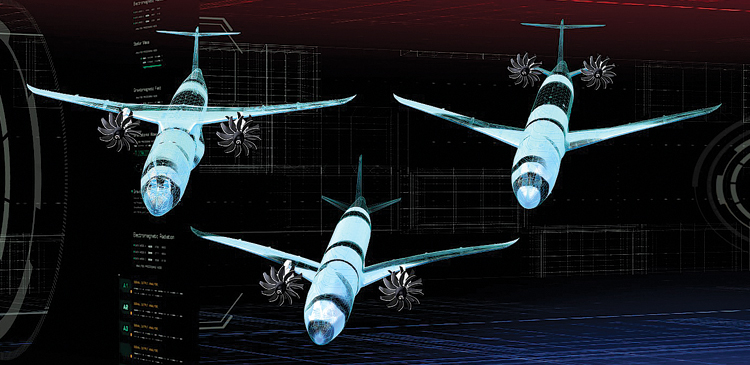

At present, GE is developing the next suite of engine technologies that includes open fan architectures, hybrid-electric and electric propulsion concepts, and advanced thermal management concepts. All of these offer the potential to achieve at least a 20 per cent additional improvement in fuel efficiency.

In the product spotlight for sustainability, GE highlighted its GE9X engine as the most efficient engine that the manufacturer has built on a per-pounds-of-thrust basis. It is designed to deliver up to 10 per cent greater fuel efficiency than its predecessor, with emissions of nitrogen oxides (NOx) 55 per cent below current regulatory requirements.

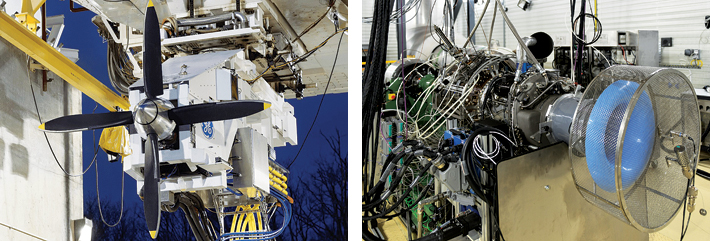

GE has also embarked on multiple engine technology demonstrators to accelerate emissions-lowering technologies for aircraft propulsion. Two recent examples include the CFM Program and the Electric Powertrain Flight Demonstration (EPFD) project.

The CFM RISE programme will use hybrid electric capability to optimise engine efficiency while enabling electrification of many aircraft systems

Partnering with the US National Aeronautics and Space Administration (NASA), GE Aviation announced it has launched a programme to mature an integrated megawatt class hybrid electric powertrain. This will demonstrate flight readiness of a hybrid electric propulsion system for single-aisle aircraft, with ground and flight tests taking place by the mid-2020s. As part of NASA’s EPFD project, a total $260 million will be invested by NASA, GE Aviation and partners over five years.

GE and the US FAA (Federal Aviation Administration) will also invest nearly $55 million over five years to accelerate development of a series of technologies for more sustainable aviation, as well as ongoing research into alternative jet fuels through the FAA‘s Continuous Lower Energy, Emissions and Noise (CLEEN) programme. This is the third CLEEN award for GE Aviation since 2010.

SAFRAN

Very recently Safran Helicopter Engines completed the first end of a helicopter engine test campaign using 100 per cent SAF. During this campaign, a Makila 2 ran on a biofuel produced by TotalEnergies from residues and waste from the circular economy, specifically used cooking oil.

This test campaign has evaluated the operational impact of using only SAF on a helicopter engine. To do this, the engine manufacturer utilised a Safran Tech special facility known as “Bearcat” (Banc d’Essai Avancé pour la Recherche en Combustion et Aérothermique des Turbomachines), an advanced test bench for turbomachinery combustion and aerothermal.

Safran engines are already certified to operate with up to 50 per cent SAF. With 100 per cent incorporation, the lower carbon footprint of these fuels will reduce CO2 emissions by up to 80 per cent.

In addition to that the first A319neo flight with 100 per cent SAF was also successfully done. With this Airbus, Dassault Aviation, ONERA, the French Ministry of Transports and Safran have launched the first in-flight study of a single-aisle aircraft running on unblended SAF.

GE & SAFRAN’S CFM RISE PROGRAMME

GE Aviation and Safran launch advanced technology demonstration programme for sustainable engines, extending CFM partnership to 2050. An advanced technology development programme that aims for over 20 per cent lower fuel consumption as well as CO2 emissions compared to the existing engines was launched in June by the two companies. The CFM RISE (Revolutionary Innovation for Sustainable Engines) programme targets to demonstrate and mature a range of new, disruptive technologies for future engines that could enter service by the mid-2030s.

The programme also aims to ensure 100 per cent compatibility with alternative energy sources such as SAF and hydrogen. The RISE programme builds on CFM engines’ advanced materials and aerodynamics for the next generation of aircraft engines that could be available by mid-2030s. In addition to that, the mix of ceramic fibres and ceramic resin is one-third the weight of metal alloys and more heat resistance. Ceramic matrix composites, or CMCs has one-third the weight of steel and can withstand temperatures as high as 2,400 degrees Fahrenheit (beyond the melting point of many advanced metallic super alloys) further improving an engine’s thermal efficiency.

The programme will use hybrid electric capability to optimise engine efficiency while enabling electrification of many aircraft systems. Over 300 separate component, module and full engine builds are a part of the programme. The engine design promises to increase overall fan pressure ratio while simultaneously reducing rotor loading, in turn making way for higher maximum flight Mach number.

A demonstrator engine is scheduled to begin testing at GE and Safran facilities around the middle of this decade and flight test soon thereafter. The planned demonstrator engine will also include 3D-printed components, hybrid-electric systems, advanced heattransfer circuits and other breakthrough technologies.

ROLLS-ROYCE

Rolls-Royce recently announced the completion of the first flight of their all-electric ‘Spirit of Innovation’ aircraft. The plane took to the skies propelled by its powerful 400kW (500+hp) electric powertrain with the most power-dense battery pack ever assembled for an aircraft. The manufacturer highlighted this as another step towards the plane’s world-record attempt and another milestone on the aviation industry’s journey towards decarbonisation.

Rolls-Royce launched MTU hydrogen solutions for power generation. From 2022, the MTU Series 500 and Series 4000 are expected to be ready for 25 per cent hydrogen, and from 2023, the MTU engines and conversion kits would be available for 100 per cent hydrogen

The ‘Spirit of Innovation’ is a way in which Rolls-Royces aims in helping decarbonise the critical parts of the global economy in which we operate.

Additionally, Rolls-Royce launched MTU hydrogen solutions for power generation. From 2022, the MTU Series 500 and Series 4000 are expected to be ready for 25 per cent hydrogen, and from 2023, the MTU engines and conversion kits would be available for 100 per cent hydrogen. The company is further advancing its MTU gas engine portfolio for power generation and cogeneration to run on hydrogen as a fuel and thus enable a climate-neutral energy supply. Already today, gensets powered by MTU Series 500 and Series 4000 gas engines can be operated with a gas blending of 10 per cent hydrogen.

Working with Boeing and World Energy, Rolls-Royce also carried out a successful test flight of its 747 Flying Testbed aircraft using 100 per cent SAF on a Trent 1000 engine running solely on 100 per cent SAF while the remaining three RB211 engines ran on standard jet fuel.

With electric and hybrid-electric propulsion seen as among the most promising technologies for mitigating several environmental issues, Rolls-Royce also teamed up with Airbus and Siemens to work on a new hybrid-electric technology flight demonstrator, E-Fan X.

All these efforts are significant for the industry that aims to achieve net zero emissions by 2050. These and many other manufacturers are participating in important initiatives to ensure the industry advances towards sustainable flight and greener skies sooner.