Sustainable and Green Aero-Engines

New aircraft and engine designs/technologies and alternative materials need addressing

The terms ‘Sustainable Aviation’ or ‘Green Aviation’ are increasingly being used to address the technological and socio-economic issues facing the aviation industry to meet the environmental challenges of the twenty first century. Air travel continues to see very high growth especially in major developing nations and emerging economies. Global aviation contributes two per cent of global GreenHouse Gas (GHG) emissions and supports eight per cent of the world economic activity in terms of GDP. As a result of massive increase in air travel by 2025, it is estimated that the total carbon dioxide (CO2) emission from commercial aviation may reach 1.5 billion tonne. The amount of nitrogen oxides (NOx) around airports may rise from 2.5 million tonne in 2000 to 6.1 million tonne by 2025. Because the majority of aircraft emissions are injected into the upper troposphere and lower stratosphere, the resulting impacts are unique. The impact of burning fossil fuels at altitude is approximately double that due to burning the same fuels at ground level. The number of people who may be seriously affected by aircraft noise may rise from 24 million in 2000 to 30.5 million by 2025. Therefore, there is an urgency to address the problems of emissions and noise abatement through technological innovations. New aircraft and engine designs/technologies and alternative materials need addressing. The most important role in an airplane’s fuel efficiency is of the engines. The two mostwidely used aircraft today - the Boeing 737 and the Airbus A320 have shown that newer models carry more passengers and payload while burning 23 per cent less fuel.

SAGE INITIATIVES

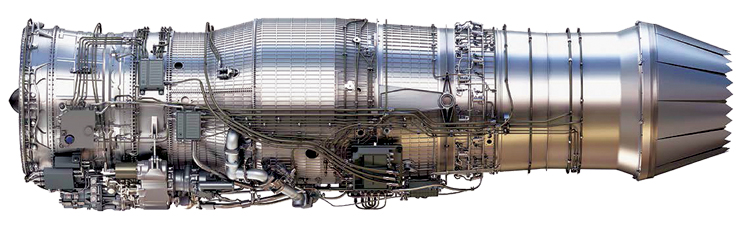

‘Sustainable and Green Aero-Engines’ initiatives are being taken both in the European Union and in the United States (US) to develop aero-engine technologies with new engine architectures that offer opportunities for reduction in CO2 emissions relative to current turbofans. Emissions of CO2, H2O, O2 and N2, which are products of hydrocarbon fuel combustion, are all functions of engine fuel burn efficiency. Areas being addressed are lightweight low pressure systems for turbofans, including composite fan blades and high efficiency low pressure turbine; advanced engine externals and installations including novel noise attenuation; high efficiency Low Pressure (LP) spool technology while further advancing high speed turbine design; option of an aggressive mid-turbine inter-duct; high efficiency and lightweight compressor and turbine; and low emission combustion chamber for next generation rotary-craft engine. Developments in controls and electronics, lightweight metallic and composite materials, hydraulic and pneumatic systems, novel manufacturing methods, specific aero-engine parts such as casing, tanks, pipes, high temperature materials such turbine blades and sensors would require attention.

SAGE 2 PROJECT

European Union’s SAGE 2 project headed by Rolls-Royce and Safran focuses on demonstrating the technologies such as composite propeller blades with aero-acoustic optimisation, electric de-icing system and equipment. The gas generator used in the SAGE 2 open rotor demonstrator is derived from a Snecma M88 engine. The current status plan is to use the Airbus A340-300 MSN001 test aircraft as a flight test vehicle, with one full size Contra Rotating Open Rotor (CROR) pusher engine attached to a representative pylon and engine mount. Open rotor technologies offer the potential for significant reductions in fuel burn and CO2 emissions relative to turbofan engines of equivalent thrust. Open rotor engines remove the limitation by operating the propeller blades without a surrounding nacelle, thus enabling ultrahigh bypass ratios to be achieved. Installation of the open rotor engine on the airframe has its complexities, as the airflow through the propellers interacts with the supporting airframe structure in a different manner. The trend to Very High Bypass Ratio (VHBR) engines requires technology developments across a broad range of complex gas turbine systems, from fan inlet through the complete compression, combustion and turbine to exhaust.

CAEP TARGETS

Aircraft engines account for most of the noise and fuel consumption characteristics of airplanes. The International Civil Aviation Organization (ICAO) has a Committee on Aviation Environmental Protection (CAEP) since 1983. Aircraft are required to meet the engine certification standards adopted by ICAO. Of particular relevance is the Standard for NOx, a precursor for ozone, which at altitude is a GHG. The standard for NOx was first adopted in 1981, and was made more stringent in 1993, 1999, 2005 and 2011. The CAEP/8 standard was set in 2010, in which the medium and long-term NOx technology goals were to target reduction by 45 per cent of CAEP/6 standard by 2016 and 60 per cent by 2026. These targets have yet to be met fully. Novel cycles that increase bypass ratios, incorporation of lean burn technology are evolving. ICAO is developing the first non-volatile PM (nvPM) standards (covering soot or black carbon particles) for turbofan/turbojet engines. Similarly for turboprops, helicopter turbo-shaft, and APU engines, the nvPM standard will help better assess impact.

A ‘GREEN’ DESIGN CHANGE CAN BE SEEN IN THE BLENDED WING AND BODY OF THE SUBSCALE, FLYING X-48B AIRCRAFT PROTOTYPE

DESIGN CONSIDERATIONS

Changes in engine design or operation might include ultra-high bypass turbofans; open rotor engines; use of alternative fuels and relocating engines on the body of the aircraft such that engine noise gets deflected upwards. An example of a ‘green’ design change can be seen in the blended wing and body of the subscale, flying X-48B aircraft prototype. Other concepts may include capitalising on the potential of advanced electrical power technologies such as batteries or fuel cells to reduce the amount of fuel needed. Using high-tech engines, propeller efficiency, advanced aerodynamics and low-drag airframe can result in higher fuel saving and less gaseous emissions. Improvement in performance can be achieved by moving from a component-based design to a fully integrated design by including wing, tail, belly fairing, pylon, engine and high lift devices into the solution. At the April 2018 ILA Berlin Air Show, a high-efficiency composite cycle piston-turbofan hybrid engine for 2050, combining a geared turbofan with a piston engine core was presented. The 2.87-metre diameter, 16-blade fan gives a 33.7 ultra-high bypass ratio. The 11,200 lb engine could power a 50-seat regional jet. Although the engine weight increases by 30 per cent, the overall aircraft fuel consumption reduced by 15 per cent.

ELECTRIC AND SOLAR ENGINES

A number of electrically powered aircraft such as the QinetiQ Zephyr have been designed since the 1960s. In 2007, France flew a conventional light aircraft powered by an 18kW electric motor using lithium polymer batteries and became the first electric aircraft to receive an airworthiness certificate. Solar-powered manned aircraft designed to fly both day and night without the need for fuel, are already under development. Solar electric propulsion has been performed through the manned ‘Solar Impulse’ and the unmanned NASA ‘Pathfinder’ aircraft. Several big companies such as Siemens are developing high performance electric engines for aircraft. Small multi-copter UAVs are almost always powered by electric motors.

NEW ENGINE CONCEPTS

Two new engine concepts currently under investigation include the ‘Combined Brayton Cycle Aero Engine’ and ‘Multi-Fuel Hybrid Engine’. Even though modern engines are supposedly very efficient, over 50 per cent of the energy input is ejected as waste heat. Improving performance by heat recovery is the requirement. A heat exchanger integrated in a turbofan core can convert recovered heat into useful power which can be used for onboard systems or to power an electrically driven fan to produce auxiliary thrust. A dual combustion chamber, with first stage between HP Compressor and HP Turbine burning Hydrogen/Methane cryogenic fuel or liquid natural gas and the second combustor at an inter-stage uses kerosene/bio-fuel in the flameless combustion mode, is being considered. High temperature generated in the first stage, allows flameless combustion in the inter stage thus reducing CO2 and NOx emissions. Cryogenic bleed air cooling can enhance the engine thermodynamic efficiency by cooling the bleed air thus allowing increase in temperature of the fuel. Contra-Rotating Fans can use boundary layer ingestion to reduce both noise emission and improve propulsive efficiency.

NEXT GENERATION INNOVATIONS

Developed under the US Department of Defense’s Adaptive Versatile Engine Technology (ADVENT) and Adaptive Engine Technology Development (AETD) programme is the GE Adaptive Cycle Engine (ACE). Unlike traditional engines with fixed airflow, the GE ACE is a variable cycle engine that will automatically alternate between a high-thrust mode for maximum power and a high-efficiency mode for optimum fuel savings. ACE is designed to increase combat aircraft thrust by up to 20 per cent, improve fuel consumption by 25 per cent to extend range by more than 30 per cent and provide significantly more aircraft heat dissipation capacity. These adaptive features are coupled with an additional stream of cooling air to improve fuel efficiency and dissipate aircraft heat load.

SOLAR-POWERED MANNED AIRCRAFT DESIGNED TO FLY BOTH DAY AND NIGHT WITHOUT THE NEED FOR FUEL ARE ALREADY UNDER DEVELOPMENT

With a joint GE/US Government investment of over $1 billion, the ACE engine will incorporate both heat-resistant materials and additive manufactured components. In the ADVENT programme, GE reached the highest combined compressor and turbine temperatures ever. The Adaptive Engine Transition Programme (AETP) is underway. The challenge remains in going to higher overall pressure ratio engines due to increasing cooling air temperatures, constraints imposed by developing new material technologies and detrimental weight and drag impact on ultra-high bypass ratio engines. GE Aviation’s Passport engines feature a higher pressure ratio and a compressor made of new – and unnamed – advanced materials. GE predicts that the engines will achieve eight per cent lower fuel consumption and considerably lower NOx emissions. The Pulse Detonation Engine (PDE), which has the potential to radically increase thermal efficiency, is one of the more exciting propulsion technologies being researched. PDE uses detonation waves to combust the fuel and oxidizer mixture. Instead of burning it, it explodes it. In theory, it can be used up to Mach 5.0.

Some of these statistics around aero-engines can explain the challenges. Each wide-chord fan blade exerts a centrifugal force of around 70 tonne - equivalent to the weight of a modern locomotive; each high-pressure turbine blade generates the same amount of power as a Formula-1 car; and the turbine discs will now have a ‘dual microstructure’ to give different mechanical properties at the centre and at the edge of the disc. Each kilogramme of fuel saved reduces carbon dioxide (CO2) emissions by 3.16 kg. Modern aircraft are 40 per cent more efficient than those of 15 years ago. Fixed electrical ground power can reduce the amount of fuel burn used on ground by up to 85 per cent. Aero-engines of the future will be more and more fuel efficient and environment friendly.