Redesigned. From Nose to Tail New E-Jets E2s

Embraer’s competitors and industry analysts often characterise the Brazilian manufacturer’s second-generation E-Jets as having just a few superficial design changes compared to the first-generation. In fact, the E2s are radically different. You might even say they’re completely new airplanes.

Standing beside the prototype E190-E2 at Embraer’s factory in São José dos Campos, you first notice the sheer size of the Pratt & Whitney PW1900G engines in proportion to the aircraft. At slightly more than two metres in diameter, they’re big. The wings, with their swept tips, are an elegant gull shape. Those are the most visible characteristics of the E2. Yet it’s the things you can’t see—new avionics, a roomier cabin, simplified maintenance, better operating economics—that really tell the story of a generational leap with the E-Jets family.

Recognising the global trend to larger-capacity jets, Embraer dropped plans early on for a 70-seat E2 and is on schedule to deliver three 76 to 130-seat variants between 2018 and 2020. Given that the structural and economic utility of most commercial airplanes averages about 20 years, the timing of the new E2s coincides with the service life of the first E-Jets that were delivered in early 2004. According to John Slattery, Embraer’s President of Commercial Aviation, “in the product life-cycle, the airplane family is maturing. Some might even consider it approaching middle age.”

So, how is Embraer keeping its E-Jets concept current?

GIVEN THAT THE STRUCTURAL AND ECONOMIC UTILITY OF MOST COMMERCIAL AIRPLANES AVERAGES ABOUT 20 YEARS, THE TIMING OF THE NEW E2S COINCIDES WITH THE SERVICE LIFE OF THE FIRST E-JETS THAT WERE DELIVERED IN EARLY 2004.

Knowledge and Technology

Advances in technology helped shape the E2 design yet Slattery is quick to give some perspective. “There’s often a lot of noise associated with new technology. Of course, many advancements are truly progressive. But what we’ve learned over the years is that it’s more important to introduce new technology when it adds real value and not just because some new technology is on the market. Customer dialogue helps us determine that value.”

Embraer also builds business and defence aircraft which offers a unique benefit when designing new airplanes. “We can adapt a technological innovation from one division to a new product in another division. That cross-technology philosophy helped in the development of the E2s which, contrary to some of our critics who claim the changes are purely cosmetic, carry over only 25 per cent of the design and component aspects from the first-generation E-Jets,” says Slattery.

Bridging the Generation Gap

Whenever a manufacturer announces a new model, it runs the risk that customers will postpone fleet acquisitions until the new airplane comes online. Why commit to today’s version when you can wait a few years for the new one? Embraer recognised that it needed to maintain its current E-Jets production skyline until the first E2s deliveries started.

To keep the order book filled in the interim, it introduced a package of aerodynamic improvements for the first-generation airplanes. The most visible of these is wingtips on the E175 that reduce fuel consumption. That modification helped the manufacturer capture the majority of new aircraft orders from regional airlines in the huge USA market in the last few years.

The decision to introduce the E2s will likely ensure current customers who have invested in first-generation E-Jets will be able to migrate to the new models well into the next decade. Slattery adds that “although the E2s have new wings, engines, avionics and interiors, they retain similar flying characteristics that allow pilots to transition easily from one generation to the next.”

Just what makes the E2s so different?

What you see...

Through the use of aluminium alloys, Embraer was able to introduce a new wing that has the highest aspect ratio among single-aisle airplanes. The wing also required a new centre fuselage section and stub. The E2’s high bypass ratio (up to 1:12) Pratt & Whitney geared turbofan engine (GTF) has fewer stages and parts than the GE engine on current-generation E-Jets. The GTF has a lower core temperature, reduces emissions by double-digits compared to engines with traditional architecture, and requires less maintenance for longer time on wing. The new engine also reduces the noise footprint by 60 per cent and the landing gear is bigger to accommodate the bigger engines.

…and what you don’t

But what’s inside is equally differentiating. The E2’s fouthgeneration fly-by-wire system is completely new. Its digital closed-loop control improves flying qualities by establishing a more aft centre of gravity on the aircraft. That, in turn, reduces the pitch moment that must be counter-balanced by the horizontal stabiliser. Consequently, the E2’s horizontal stabiliser is smaller, weighs less, produces less drag, and the aircraft burns less fuel.

WITH FEWER SHOP VISITS AND LONGER INTERVALS BETWEEN INSPECTIONS, THE AIRPLANE IS MORE PRODUCTIVE. EMBRAER ESTIMATES THAT MAINTENANCE COSTS ARE UP TO 25 PER CENT LESS PER SEAT COMPARED TO CURRENT-GENERATION E-JETS.

Embraer also became the main integrator for control laws, something it could do after the experience it gained through the design of its Legacy 500 business jet and new KC-390 military transport. Closedloop control laws improve protection in all aspects of the flight envelope, even reducing aircraft oscillations during turbulence for a smoother ride. Pilots accustomed to five flight displays in the cockpits of first-generation E-Jets will find four display screens on the E2s that are 45 per cent larger and touchcontrolled. New avionics software includes graphical flight planning, synthetic vision, and continuous situational awareness of the flight path, terrain and navigational environment regardless of the time of day or weather conditions. Navigation on the E2 is more interactive - NAVAIDs, meteorological, traffic, and ground proximity data can all be overlaid on any screen to give pilots whatever information they need to reduce their workload.

The E2’s next-generation FMS ensures the most economical performance of the aircraft. The FMS can calculate the ideal aircraft speed and operating profile to assure an on-time arrival, all at the optimal cost. Flight controls, hydraulic systems, steering and ice protection have also been enhanced.

Maintainability has made a generational leap, too. The E2 has no calendar limitations for maintenance. With fewer shop visits and longer intervals between inspections, the airplane is more productive. Embraer estimates that maintenance costs are up to 25 per cent less per seat compared to current-generation E-Jets.

In addition to a real-time aircraft health monitoring system that identifies in-flight faults and initiates remedial actions prior to landing, the E2 is E-enabled. Today’s technology means yesterday’s laborious manual processes, paper reports, printed publications and logbooks, and time-consuming transmission of information are things of the past. E-enabled architecture links everyone and everything that interacts with the E2 in the air and on the ground, digitally, wirelessly, anywhere, anytime, instantly.

Beauty on the Inside

If you’ve been in the E2 cabin mock up, you’ve seen how Embraer has re-engineered the use of space. Its innovative, staggered, premium-class seats epitomise the E2’s philosophy that emphasises personal space. Passengers have individual controls for reading and airflow. Bins were redesigned to have 30 per cent more capacity and can accommodate carry-on bags, wheels in.

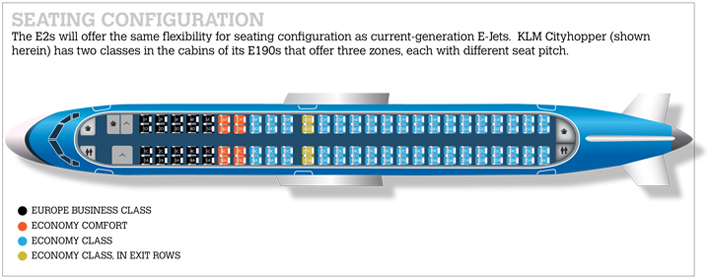

What may not be apparent is how easily the E2 can be reconfigured. An innovative seat-rail design, including row spacing in half-inch increments, allows airlines, and especially leasing companies, to change the cabin layout as they wish, quickly and cost-effectively. Many interior structures are modular for easy access and maintenance. The innovations in the E2 cabin are so impressive that Embraer won the aviation industry’s 2015 Crystal Cabin Award for Industrial Design and Visionary Concepts.

To market. On time

Embraer sees the E2 breaking traditional perceptions about regional jets. It claims that its two largest E2s, the E190-E2 and E195-E2, have between 15 per cent and 20 per cent lower fuel burn per trip than the A319neo and B737 MAX. Can the E2s compete with the two industry giants, especially in India? Slattery says: “We’ve developed a version of the E195-E2 with 132 seats that we believe is ideal in highly-competitive, low-fare markets.”

Probably the most noteworthy thing about the E2s is not the extent of the changes—they are certainly more than cosmetic. The first metal was recently cut for the E175-E2, the second of three E2s, and the overall production, flight test and certification programme is running right on schedule. The timing bodes well for Air Costa which has ordered up to 100 E2s, the first of which will be delivered in 2018.

The author is a 35-year aviation industry veteran. He was a former domestic airline pricing director for Air Canada and global marketing director at Bombardier and Embraer.