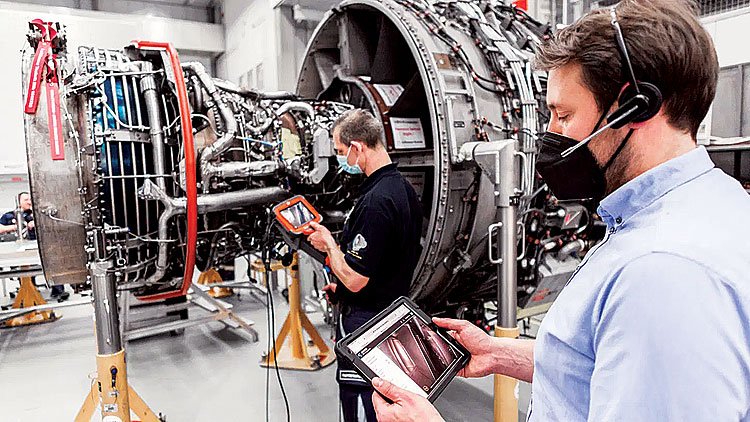

MRO Innovations

The onset of the digital revolution in aviation is transforming the MRO sector with advanced technologies

Demand for maintenance, repair and overhaul (MRO) services in India will bloom rapidly with domestic fleet expected to be more than 1,000 by 2027 from nearly 700 as of March 2023. In India, revenue of domestic MRO services providers is expected to triple to 5,500 - 6,000 crore by fiscal 2028 from about 1,800 crore currently, due to the strong growth in domestic civil aviation, government support, and ongoing MRO capex at airports.

OEM facilities across the globe that were temporarily closed during the pandemic had created shortage of parts and the scarcity of labour & raw materials resulting in slow post-pandemic recovery. This has resulted in Globalisation 2.0 which is More Dual Sourcing & Near-Shoring. The sales of OEM new freighter aircraft are bouncing back and demand for Passenger to Freighter (P2F) conversions are increasing. Engine and airframe MROs are also benefitting from additional MRO demand from the very old maintenance intensive aircraft due to their delayed retirement.

Technologies such as AI, Digital Twins, AR, Blockchain, Additive Manufacturing, Cloud Computing, real-time monitoring of aircraft condition and predictive maintenance, are the tools for service providers to manage with the reduced MRO budget of airlines. The increasing digitalisation of MRO to improve efficiency and reduce aircraft downtime is the key factor projected to propel the digital MRO market. However, such innovation would require changes not only in the industry culture but also from the safety regulators. According to a global newswire report the digital MRO market is projected to grow to $4.7 billion by 2030.

ARTIFICIAL INTELLIGENCE

Aircraft technicians are scarce and with the increasing worldwide aircraft fleet and aging of technicians, the situation is likely to get worse. Royal Netherlands Aerospace Centre has developed a new tool to diagnose failures using Artificial Intelligence. It is AI software that looks at the failure modes of previous repairs and the aircraft usage to determine the relation between aircraft and system usage and the actual failure modes of repaired parts. It then uses these relationships to diagnose components or systems and identify the failure modes. To make the outcomes of failure diagnosis acceptable for maintenance personnel, the algorithms use explainable Artificial Intelligence. It not only identifies the failure modes, but also explains why a specific failure mode occurs. This means that it is a useful tool to determine the failure mode of parts removed in serviceable condition based on predictive indicators. It helps the shops to repair these parts and reduces no-fault-founds.

The digital MRO market is projected to reach $4.7 billion by 2030, driven by technologies such as AI, Digital Twins, AR, Blockchain, Additive Manufacturing, and Cloud Computing, offering tools for efficient management within reduced MRO budgets

Airlines are increasingly connecting Artificial Intelligence to their MRO Strategies. Airlines based in the US, Europe and Asia have been adopting AI tools in the form of intelligent agents for data modelling and simulation, cognitive computing and predictive data analytics. A challenge exists for airline maintenance teams dealing with the large amount of data being produced by newer generation aircraft. Right now, Delta Air Lines is working on adopting artificial intelligence and machine learning into its aircraft maintenance strategy and has a five-year plan for officially adopting artificial intelligence into its predictive maintenance strategy. The use of artificial intelligence will be primarily to replace todays human tasks of ingesting, aggregating and analysing raw data transmitted by aircraft.

Airbus has emerged as an industry leader in introducing the use of artificial intelligence into airline maintenance operations. Airbus has established Skywise as its official predictive maintenance and advanced data analytics platform. It serves as a singular access point to data analytics that combine multiple sources into one secure cloud-based platform, including work orders, spares consumption, components data, aircraft/fleet configuration, onboard sensor data and flight schedules. The Airbus AI Gym, is pursuing to identify new and unexpected changes in the behaviour of monitored systems, as well as analyse suspicious behaviour for potential faults and failures more efficiently.

DIGITAL TWINS

These are digital replicas of aircraft or aircraft components. Data sensors are embedded in well-thoughtout locations to create this digital replica. These sensors work together to develop a real-time picture of aircraft performance. Aircraft companies use them to test new designs and predict how they will perform in the real world. Some of the biggest names in aviation already use this in MRO technology. Digital twins make it possible for aviation mechanics to monitor physical components while the aircraft is in the air. They can then plan maintenance resolving any potential issues that arise.

The structural integrity of an aircraft is sustained by repeated and costly inspections. Application of a reliable Structural Health Monitoring (SHM) system formultiple load path structures therefore is an interesting application area to reduce the cost of ownership and to improve the system operational availability. This prevents costly periodic inspections and allows maintenance on demand after the system flags a partial failure. SHM technologies based on opticalfibre Bragg grating (FBG) sensors have been developed by Royal Netherlands Aerospace Centre for multiple load path structural components. An FBG is a small segment in an optical fibre that causes a shift in wavelength due to stretching or compressing of the fibre which can be correlated with a strain value. A valuable data input for digital twin.

SMART EQUIPMENT TECHNOLOGY

Prior to the introduction and widespread use of sensors and smart equipment, maintenance followed a predictable routine. Now, as sensors and Internet of Things (IoT) technology becomes more accessible and inexpensive, manufacturers are able to track equipment performance and maintenance needs, greatly reducing or eliminating the cost inefficiencies of outdated routines. Digitisation and smart technology produce vast amounts of data. This data is used to analyse supply chain performance, enabling manufacturers to provide more information to suppliers and develop true partnerships. This results in all across benefits from pricing to turnaround time. Digital MRO technology driven productivity should be the new normal in enhancing Digital MRO. The resultant dynamic manpower planning & scheduling with Real-time production control & critical path management will usher in efficiencies and improved TAT benefiting MRO cost optimisation.

Artificial Intelligence is becoming integral to MRO strategies, addressing the scarcity of aircraft technicians by introducing diagnostic tools providing explainable AI for failure diagnosis

DRONE USAGE

Drones have become increasingly common in the world of MRO. Technicians use them for various tasks during inspections and repairs. These machines are convenient for hard-to-reach spaces and areas that pose a high risk for human workers. The main difficulty of using drones stems from regulatory differences around the world. America currently has some of the strictest rules, making it difficult to enjoy the full scope of benefits drones bring to the inspection and MRO process. The Royal Netherlands Aerospace Centre has developed ARVI (Autonomous Robot for Visual Inspections), a clever robot system which is able to map inspection areas and identify defects such as dents, scratches, broken wires, arcing, corrosion, dirt, leakages and many more. It uses an autonomous vehicle to move the sensor system to the inspection areas. ARVI can navigate through the hangar and through aircraft just like human technicians avoiding collisions and positions the sensor system autonomously.

CLOUD-BASED MRO SOLUTIONS

Aviation MRO requires a significant investment in physical assets. Consequently, cloud computing removes the need for one set of digital physical assets: servers and IT space. The cloud manages maintenance schedules and keep track of aircraft components making it easier to share data across global MRO teams.

Digital Twins, Smart Equipment Technology, Drone Usage, Cloud-Based MRO Solutions, Blockchain, Augmented and Virtual Reality, and Additive Manufacturing are reshaping the MRO landscape, bringing efficiency, cost optimisation, and innovation to the forefront of the industry

Customer Service Apps make information like price checking, availability of parts or repair services, placing orders, or obtaining the pending delivery status available. They also help conduct inventory cycle counts from time to time, ensuring an accurate and reliable inventory level. Work in Progress (WIP) accounting applications are boon for independent MROs since it is used for supporting accurate WIP accounting. Mechanics can now record the time they work on their tasks, and the firms can use it to optimise and find accurate costing, increasing their efficiency and profit.

BLOCKCHAIN

We’ve all heard of blockchain in a cryptocurrency-related context. However, this technology finds more use-cases, including “record-keeping.” MRO teams generate a lot of data which needs to be kept secure and tamperproof. Blockchain technology assists in this process by allowing the data stored to be viewed only by those with a key. What makes this technology ideal is that it is cost-effective and requires minimal maintenance. MRO teams can keep track of mechanical parts, leases, inventory, digital twinning, supply chain, repairs, etc., through blockchain. Companies are yet to fully realise such technology for application in the aviation industry. This will gain traction in MRO as more use cases and regulatory trust is accepted by the environment.

AUGMENTED AND VIRTUAL REALITY (AR/VR)

In today’s world, augmented reality is experienced through glasses or eyewear, which can provide additional data to the viewer about what they’re seeing. It is gaining popularity in the aviation industry, where MRO professionals are being trained with AR in aircraft maintenance. Augmented reality is used to visualise virtual 3D models of aeroplanes that MRO teams will be repairing, thus eliminating the need for expensive physical props. Additionally, they can all view the same model, which help facilitate teamwork. Augmented reality is being used in aviation training camps in Europe, and the technology may soon be rampant in India as well.

ADDITIVE MANUFACTURING

Additive manufacturing is already gaining popularity in the MRO sector. It uses computer-aided-design (CAD) software or 3D object scanners to direct hardware to deposit material, layer upon layer, in precise geometric shapes. Additive manufacturing enables the industry to print substantial, durable, and lightweight replacement parts that are quick and affordable and reduce the cost for maintenance providers. This is a disruptive technology which has the potential to change the way we look at MRO.

MRO & OEMS COOPERATION AND COMPETITION

The way in which MROs and OEMs have cooperated & competed has evolved over time. OEMs had largely left the MRO market to aftermarket independent and airline-affiliated MROs. During the last two decades, airframe, aircraft system and component OEMs have stepped in to compete with the independent and airline-affiliated MRO suppliers. Given the immense advantage OEMs have with intellectual property, design data and manuals, many of the larger MROs have chosen to partner with OEMs rather than competing. The trust generated through a strategic partnership with an OEM also leads to additional opportunities, thereby reflecting the twoway nature of OEM-MRO partnerships. The OEM-MRO industry is notorious for ‘coopetition’ – a combination of cooperation and competition. In the engine MRO space, there is more collaboration between MROs and OEMs. The component MRO space will continue to see significant consolidation and M&A activity.

BHARAT MRO

Global Maintenance Management developments in civil aviation will now create smarter organisations by providing managerial decision support tools and consultancy services for strategic challenges. Aviation Maintenance Technology innovations will allow cutting-edge knowledge and technologies to automate maintenance tasks and processes using robotics, prognostics and artificial intelligence. Similarly, Maintenance Engineering advances will drive process and product improvements, eg. with quantitative data analysis, creating smarter solutions by combining existing knowledge, techniques and methods. These will optimise maintenance operation, maintenance planning & resources, spares and personnel allocation. In the area of Maintenance Training, transformations will enhance training value using modern technology training devices employing virtual and augmented reality. Indian MRO therefore, must now seize the opportunity to leap frog in this sector and shun the traditional incremental approach. Capacity additions have already started. The Delhi and Bengaluru airports have set up dedicated MRO facilities for select private airlines. Plans are also in place to establish two MRO facilities near the new Jewar airport in Uttar Pradesh. Further, MRO facilities are planned to come up at the Belagavi (Karnataka), Bhopal (Madhya Pradesh) and Tirupati (Andhra Pradesh) airports. In order to attract new workforce in a market driven by skilled manpower shortages and the supply chain challenges the MRO industry will need to leverage training using virtual & augmented reality and built an MRO edifice on modern concepts. It must aggressively embrace digital MRO concepts to be competitive and efficient.