Stronger, Safer, Sustainable; P&W’s Consistent Approach

The company believes that changing today’s aircraft engines and aviation fuels would transform tomorrow’s flight

Given the drastic shifts in climate and the aftermaths of it across the world, sustainable living is at the center of every industry’s discussion. The aviation industry is no different and companies are constantly taking initiatives toward achieving sustainability. The industry even took up the target to achieve net zero emissions by 2050.

Aerospace engine manufacturer, Pratt & Whitney (P&W) is one of the companies that has been at the forefront of innovative steps towards a sustainable future. P&W joined the industrywide commitment to achieve net zero air transport carbon emissions by 2050 as it believes that the ambition to ‘fly net zero’ is an essential and defining challenge for our industry. “We’ve proven time and time again that hard work pays off when you focus on upgrading today’s products while investing in the technologies that can unleash more sustainable human progress,” stated the manufacturer.

The company believes that changing today’s aircraft engines and aviation fuels would transform tomorrow’s flight. For the same, it is making effort through three verticals:

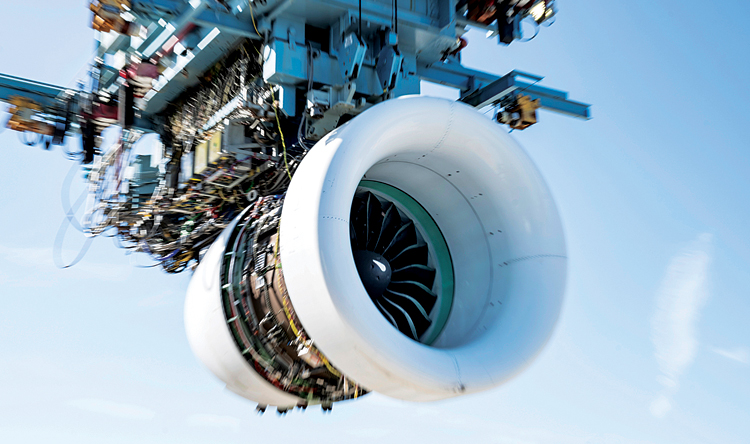

Smarter Technology: From the revolutionary GTF engine family to advanced hybrid-electric systems, P&W is continually developing technologies to make aircraft fly more efficiently and with lower emissions.

Cleaner Fuel: P&W is making aircraft engines ready for the transition to Sustainable Aviation Fuels (SAF), and developing technologies for hydrogen-fueled propulsion systems, which will be key to a net zero future for aviation.

Greener Business: P&W is cutting emissions, energy and water use, and driving recycling and solar power generation across all facilities and supply chain every day.

SOME SUSTAINABILITY INITIATIVES

SAF is believed to be a key enabler as aviation moves closer to the ultimate goal of reaching net-zero emissions by 2050. All Pratt & Whitney engines are compatible with 50 per cent SAF.

The GTF engine is at the forefront of Pratt & Whitney’s sustainability drive. P&W pioneered an industry first with its geared fan architecture, enabling a 16 per cent to 20 per cent step change in fuel efficiency, which since 2016 has already saved more than five million tonnes of CO2, relative to the existing fleet but, P&W has only just begun to tap the potential of this technology. P&W had also introduced the GTF Advantage configuration that reduces fuel consumption by an additional one per cent, extending the engine’s lead as the most efficient powerplant for the A320neo family. In total, the engine decreases fuel and CO2 emissions by 17 per cent compared to prior generation engines. Additionally, the GTF Advantage engine will be compatible with 100 per cent SAF at entry into service, helping the industry meet its 2050 net-zero commitment.

Pratt & Whitney Canada (P&WC), also participated in a longterm SAF strategy by German air rescue operator ADAC Luftrettung. To support their goal of achieving carbon neutrality for their operations, ADAC Luftrettung will extend SAF usage to its fleet of P&WC-powered helicopters.

P&W joined the industry-wide commitment to achieve net zero air transport carbon emissions by 2050 and believes that flying net zero’ is an essential and defining challenge for the industry

Last year, P&W had also opened a ceramic matrix composites (CMCs) engineering & development facility in California, an integrated engineering, development and low-rate production facility solely dedicated to CMCs for aerospace applications. Ceramic matrix composites are a class of material made of ceramic fibers embedded within a ceramic matrix. CMC materials are lightweight and can be used to manufacture engine parts that are onethird the weight of traditional metallic parts. The temperature capability of CMC parts is several hundred degrees higher than state-of-the-art superalloy parts. This translates into a significant improvement in fuel efficiency as well as weight savings, with the added benefit of reduced emissions and carbon footprint.

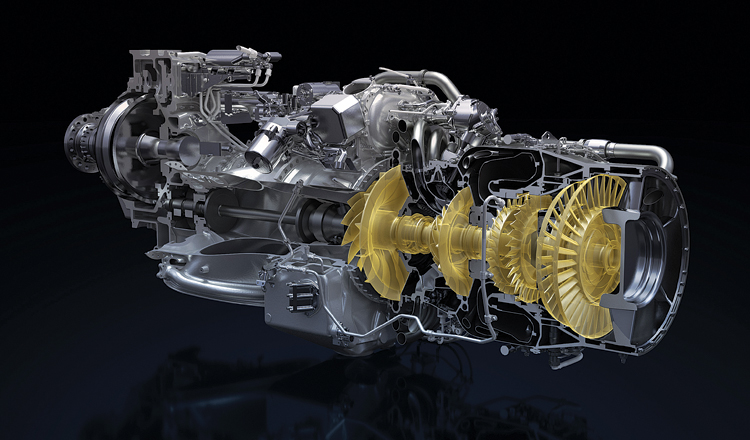

P&WC had also announced its new regional turboprop PW127XT engine series, designed with the latest materials and technologies to deliver the next level of efficiency, time-on-wing and service. The company celebrated the launch with ATR, with the PW127XT-M engine that is purpose-built to offer word-class reliability and increased value for ATR 42/72 aircraft.

Regional turboprops consume 40 per cent less fuel and emit 40 per cent less CO2 emissions than regional jets on flights up to 400 nautical miles. The PW127XT-M engine builds on the economic and sustainable propulsion advantage of existing PW127M powered aircraft, with a 3 per cent improvement in fuel efficiency. Like all P&WC engines, the PW127XT-M engines are certified for up to a 50 per cent sustainable aviation fuel blend. The PW127XTM engine offers increased savings to customers, specifically:

- 40 per cent extended time on wing by moving to the right the schedule for both engine overhaul intervals and hot section inspections compared to the PW127M.

- 20 per cent less maintenance costs; with only two scheduled engine events over 10 years.

- Enhanced Service Experience

EH&S GOALS

With the number of commercial aircraft in service projected to grow from 29,000 today to 47,000 by 2030, P&W is ensured to be committed to deliver products and operations that won’t compromise future generations. Through their products and ground operations, P&W aims to focus on sustainability through environment, health and safety objectives.

P&W have their 2025 EH&S (Environment, Health & Safety) sustainability goals that include:

Environment Goals

- 10 per cent reduction in greenhouse gas emissions

- Greenhouse gas emission reduction continues to be a top priority for the company, and we aim for a further 10 per cent reduction from 2019 levels.

- 10 per cent reduction in water consumption. We seek to conserve water, reducing our use by 10 per cent compared with 2019.

- 10 per cent reduction in waste to landfill and incineration

- The waste reduction goal seeks to reduce waste that is buried or burned by 10 per cent from 2019 levels. These waste management methods have the most harmful environmental impacts and are the least preferred according to the US EPA waste management hierarchy.

- 100 per cent implementation of water, waste, and energy/greenhouse gas best management practices

- We are also expanding the use of best management practices to enhance our environmental programs and reduce our impacts. We have selected more than 30 best practices in the areas of water, waste, and energy/greenhouse gas for sites to implement.

P&W pioneered an industry first with its geared fan architecture, enabling a 16 per cent to 20 per cent step change in fuel efficiency

Health and Safety Goals

- 100 per cent reduction in high and elevated ergonomic risks, 50 per cent reduction in medium risks

- Ergonomic injuries (including injuries relating to lifting, lowering, pushing or pulling objects and from repetitive motion) are the leading type of workplace injuries.

- 50 per cent reduction in high chemical and noise exposure risks

- Another goal proactively targets reducing potential exposure — well beyond what is required by regulation — to certain hazardous materials such as solvents and toxic metals, and to noisy work environments.

- 100 per cent implementation of level 1 mistake proofing

- The level 1 mistake-proofing goal is a corrective action process that requires controls such as engineering changes, task redesign, or hazard isolation after all serious injuries, and lost workday injuries. This process leads to more robust corrective actions (beyond administrative controls) to prevent a recurrence.

- The final safety goal is to ensure that all operations implement a near-miss reporting system that identifies and eliminates hazards before they can result in an employee’s illness or injury. Identifying near misses — before they become injuries — is an essential step in maturing our safety culture into one that is proactive and focused on eliminating unsafe acts and conditions.

SUSTAINABILITY GOALS

In 2013, P&W had launched aggressive goals to further improve the sustainability of its factories, suppliers and products by 2025 and increase efficiencies, create added value for its customers and employees, and lead industry efforts to reduce aviation’s environmental impact. Pratt & Whitney’s global sustainability goals for 2025 – the company’s 100-year anniversary – focus on Waste, Energy, Water, Safety & Wellness, Materials, Suppliers and Products. The company’s sustainability improvements to date demonstrate a record of leadership, achievement and commitment.

P&WC’s regional turboprop PW127XT engine series is designed with the latest materials and technologies to deliver the next level of efficiency

The 2025 goals and Pratt & Whitney’s achievements to reduce its environmental impact are:

Waste: Zero Waste in the factories – 100 per cent recycled. [Since 2006, P&W has reduced its total industrial process waste by 30 per cent.]

Energy: Energy use will be optimised. Reduce greenhouse gases by 80 per cent. [Since 2006, P&W has reduced greenhouse gases by 30 per cent in its factories – 2,32,000 metric tonnes of CO2. P&W also reduced air emissions from chemicals by 60 per cent.]

Water: Reduce consumption by 80 per cent. [Since 2006, P&W has reduced water use by 39 per cent.]

Safety & Wellness: All employees will be injury-free and will have best-in-class wellness programmes. [Since 2006, P&W has decreased injury rates by 57 per cent.]

Materials: Ensure that engines are 100 per cent recyclable at the end of their life. Products will maximise the amount of recycled or reverted metals and contain no materials of concern. [For more than 15 years, P&W has actively pursued reductions in the use of materials of concern in its products and factories to ensure its manufacturing processes become green.]

Suppliers: All suppliers will have world class safety rates, will meet aggressive resource conservation targets and will be 100 per cent green certified. [P&W suppliers are required to follow a code of conduct that includes resource conservation, ethics, labour guidelines and safe workplace requirements.]

Products: The engines will be the most fuel efficient and quietest on the market. [The PurePower engine family cuts carbon emissions by 3,000 tonnes per aircraft per year, reduces aircraft noise footprints by 50 to 75 per cent, and will surpass the most stringent standards (CAEP/6) by 50 per cent for nitrogen oxides (NOx).]

Pratt & Whitney has invested almost $60 million in more than 800 environmental projects since 2006 and continued to display its leadership in global sustainability through its innovative products and services. Pratt & Whitney collaborates with suppliers and communities to reduce its global environmental footprint and increase natural resource efficiencies in its factories.