Pratt & Whitney introduces GTF Advantage

The GTF Advantage engine will be available for A320neo family aircraft starting in January 2024

Advancing its journey towards efficient sustainability, Pratt & Whitney formally unveiled the GTF Advantage engine programme recently. Introduced by the manufacturer as the world’s most fuelefficient and sustainable single-aisle aircraft engine, it is the “next revolution of GTF”. The Pratt & Whitney (P&W) GTF Advantage engine whose major customer is Airbus for its A320neo family aircraft, further extends the economic and environmental benefits of the existing GTF engine.

“Our industry faces the critical challenge of significantly reducing aviation’s impact on the environment and we, at Pratt & Whitney, are determined to be a leader in this effort.”

—Chris Calio, President, Pratt & Whitney

“GTF Advantage provides even more value to our customers, both in revenue potential and environmental impact, with lower fuel burn and new route opportunities.”

—Carroll Lane, President of Commercial Engines at P&W

The GTF Advantage configuration:

- Reduces fuel consumption by an additional one per cent, extending the engine’s lead as the most efficient powerplant for the A320neo family.

- The engine decreases fuel consumption and CO2 emissions by 17 per cent in total, compared to prior-generation engines.

- Additionally, the GTF Advantage engine will be compatible with 100 per cent sustainable aviation fuel (SAF) at entry into service, helping the industry meet its commitment to net zero emissions by 2050.

- This new configuration delivers higher thrust, both at sea level and for “hot and high” airports. With up to 34,000 pounds of takeoff thrust per engine, the Advantage configuration makes GTF the most powerful engine for the A320neo family. The higher thrust rating enables increased range and payload, unlocking more destinations for airlines.

- Significant improvements in high altitude takeoff thrust.

The current generation of P&W GTF engines for the Airbus A320neo family reduces fuel consumption and carbon emissions by 16 per cent compared to prior-generation engines and are certified to operate on 50 per cent SAF. However, going ahead P&W is aiming to achieve 100 per cent SAF compatibility.

“GTF engines met or exceeded fuel, emissions and noise commitments from day one and have since achieved a strong record of dependability and low operating cost. GTF Advantage provides even more value to our customers, both in revenue potential and environmental impact, with lower fuel burn and new route opportunities.” said Carroll Lane, President of Commercial Engines at P&W.

The GTF Advantage programme is an 11 engines programme and P&W is about a 1000 hours into the programme, with over one year of ground and flight testing complete

The GTF Advantage configuration includes technology enhancements throughout the engine core, for which P&W has already completed more than a year of ground and flight testing. The engine will be available for A320neo family aircraft starting in January 2024. An important highlight is that this new configuration will be interchangeable with already delivered engines and will become the new production standard for A320neo family aircraft, ensuring a seamless introduction for operators as well. This also means that the new and base model engines, i.e. the GTF and GTF Advantage engines will be compatible and can be intermixed, interchanged and utilised, hence expanding the value for customers as well as the manufacturer. The highlight includes, the engine is:

- Fully interchangeable: with the same aircraft interface, new model engines can replace base model engines, and vice versa, giving airlines ultimate flexibility in their operations.

- Fully intermixable: aircraft will be able to operate one of each configuration. Advanced software will make this invisible to the pilots, delivering maximum efficiency no matter the pairing.

Hence, the GTF Advantage promises to allow customers the flexibility they never had before. It also makes use of new technologies for more customer value. It is designed for durability and performance; also exploring more thrust at lower temperatures. The GTF Advantage programme is an 11 engines programme and P&W is about a 1000 hours into the programme. The gear of the programme is critical and a major enabler.

- More than a year of ground and flight testing complete

- Extensive endurance testing for high durability

- Builds on mature dispatch reliability of 99.97 per cent

- Delivers more thrust at lower temperatures

GTF Advantage Engine is promising to power sustainable aviation with new technology throughout the engine through:

- Enhanced aerodynamics

- Next gen coatings

- Optimised turbine clearances

PATH TO BETTER FUEL

Three Components Needed for Advanced Fuels

- 1. Engine & Aircraft Technology Testing with SAFs up to 100% blend Adaptation for alternative fuels, H2

- 2. Fuel Production at Scale Policy measures and incentives Sustainable feedstocks Renewable energy

- 3. Infrastructure for Delivery SAF “drop in” standard H2 Liquefaction and handling

Source: Pratt & Whitney

P&W also highlighted that the airlines who demand unmatched efficiency and environmental performance depend on GTF power for their A320neo family aircraft. They are now building upon the engine’s mature dispatch reliability, adding aircraft capability and taking these benefits to a new level. The GTF Advantage engine will extend its lead as the most efficient, most powerful engine choice for the A320neo family. This new configuration demonstrates the long runway for growth inherent to the geared fan architecture, along with our commitment to continual investment in technology, innovation and sustainability.

“We always said our geared fan architecture has a long runway for growth and future development, and the GTF Advantage demonstrates this. Our gear system, and the overall engine architecture it enables, are foundational to unlock the benefits of advanced aerodynamics, materials and systems. We are committed to continuing to invest in these technologies for the next generation of commercial aircraft,” said Tom Pelland, senior vice president of GTF Engines at P&W.

Since entering service in early 2016, GTF engines have saved operators more than 600 million gallons (more than two billion liters) of fuel and avoided more than six million metric tonnes of carbon emissions. With more than 1,100 aircraft, 58 airlines and three aircraft families – Airbus A320neo, Airbus A220 and Embraer E-Jets E2 – GTF engines have also reduced noise footprint by 75 per cent and regulated emissions by 50 per cent to the CAEP/6 regulatory standard, the official press release informed. The manufacturer believes that GTF is making the best engine better in the single aisle market.

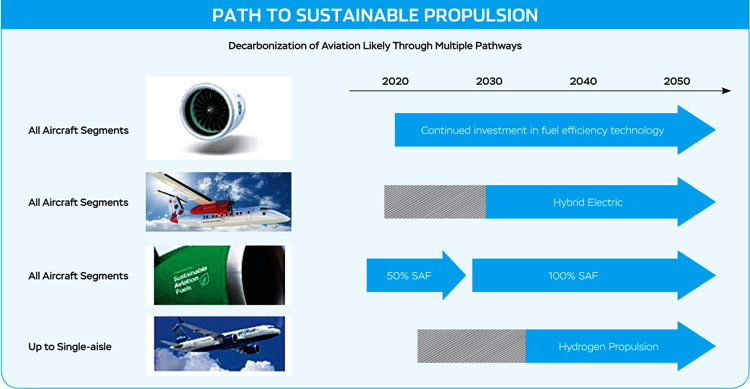

The company stated that GTF is just getting started with the geared architecture being foundational for future technologies. It’s advancing in the areas of

- Sustainable Aviation Fuels through customer collaborations and 100 per cent SAF demo flights

- Engine Efficiency through incorporating advanced materials and cooling, and higher bypass ratios

- Hybrid Electric through investments in GTF hybrid-electric systems; demonstrating system and component technologies in Canadian programme

Touted as the most sustainable engine for A320neo family aircraft, GTF is already ahead in the efficiency league and with advantage programme it is getting even more so. P&W is sure that the GTF Advantage engine will extend its lead as the most environmentally friendly option with up to 17 per cent lower CO2 emissions in compared to the prior generation engines like V2500; capability of even lower emissions with SAF and compatibility with 100 per cent SAF.

Since entering service in early 2016, GTF engines have saved operators over two billion liters of fuel and avoided more than six million metric tonnes of carbon emissions

The GTF Advantage portfolio will also be made available for India as the company believes India to already have one of the most modern and fuel efficient commercial fleets in the world. “A bulk of the A320neo fleet with airlines like IndiGo and GoFirst is currently GTF powered. With the kind of fuel economics and industry leading dispatch reliability the current engine delivers; we expect the GTF Advantage, with its incremental thrust and efficiency gains, will certainly have a market in India in future,” said Rick Deurloo, Chief Customer Officer.

“The GTF has already saved more than 150 million gallons of fuel for the airlines, and avoided 1.4 million tonnes of carbon emissions in India alone. Today, all our engines are ready to operate with SAF at up to a maximum blend of 50 per cent,” informed Graham Webb, Chief Sustainability Officer.

The company underlined that when it comes to sustainability, they are not just talking about 2035 but about today i.e. the present moment and what actions can be taken now. P&W is constantly taking steps and making strategies for powering sustainable aviation. The company is also getting into Hydrogen however, that for now is not the most feasible ways because of the low availability. Nevertheless, the research is extensively continuously on. Additionally, from more fuelefficient jet engines to lower carbon radars, Raytheon Technologies and its businesses like Pratt & Whitney, support customers’ climate goals by developing the technologies that will make those goals possible. P&W has centrally been operating through CORE (Customer Oriented Result and Excellence) as well to deliver the customers’ demands.

To ensure that they are making their contribution towards sustainability, P&W also spoke about their path to better fuel which constitutes of three components that are needed for advanced fuels.