Redesigning the Sky

The upcoming generation of aircraft is sure to look very different from what we presently witness, aiming for lighter, quieter, safer and more efficient aircraft

Aviation and innovation are almost synonymous to each other. The very basis of aviation is the constant innovation in technology that not only led to the invention of the first aircraft but has also paved way for evolution in the industry based on the demands and changing scenarios. Even now as the technology advances with various aspects like sustainability continuously coming to the forefront, the future of the aviation industry is being designed with innovative concepts that are experimenting with the structure, the materials, the propulsion, the emission, seating, fan designs, etc of the aircraft.

Further to that, the advent of robotics, artificial intelligence, the internet of things, unmanned aircraft systems, hybrid and electric airplanes and engines is making aircraft lighter, quieter, safer and more efficient. Smoother, and sustainable experimentation in design is continuously being explored. The upcoming generation of aircraft is sure to look very different from what we presently witness. It will certainly paint a very different picture of air mobility in the times ahead.

Here we take a look at some of the next generation of airplanes and how they could transform the aviation industry.

ALICE

Eviation Aircraft recently unveiled the revised design for Alice, its all-electric 11-seat aircraft, and confirmed plans to complete FAA (Federal Aviation Administration) type certification and service entry in 2024. Alice is expected to make its first test flight by year-end.

In the newly published design drawing, a T-tail configuration has replaced a V-tail one in the earlier prototype to optimise performance and handling and make it easy and reliable for pilots to seamlessly transition to flying the aircraft. Meanwhile, Alice’s two MagniX Magni650 electric motors have been relocated from the wing tips to a pylon mount on the aft fuselage.

Key programme partners announced so far include Honeywell Aerospace, which is providing Alice’s fly-by-wire flight control system, and aerostructures group GKN Aerospace.

ECOPULSE

Airbus’ EcoPulse distributed propulsion hybrid aircraft demonstrator – which is being developed by Daher, Safran and Airbus with the support of France’s Civil Aviation Research Council (CORAC) and French Civil Aviation Authority (DGAC) – successfully completed wind tunnel testing recently.

EcoPulse looks at evaluating the benefits of distributed propulsion and its possible integration on future aircraft. Distributed propulsion works by breaking down thrust generation among many small engines positioned along the span of the wing. The standard engine and propeller systems are augmented by six wing-mounted propellers, each of which is driven by 50-kW ENGINeUS electric motors powered by batteries or an auxiliary power unit. By minimising the power of each propulsor and, as a result, its mass, distributed propulsion holds the potential to unlock a range of possibilities for improved aircraft performance. This includes the following:

- Improved cruise, and take-off and landing performance

- Reduced noise due to better synchronisation between several propellers

- Increased energy savings due to reduced tail surface and better aircraft control

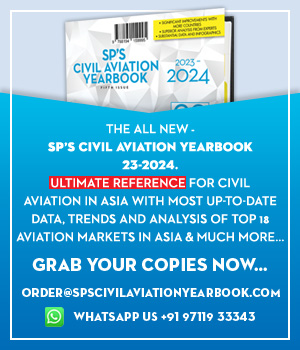

ELECTRA’S ESTOL

Electra.aero presented its first commercial product to serve regional air mobility markets in May this year. The aircraft that can carry up to seven passengers and a pilot as far as 500 miles, is designed to operate out of areas shorter than a soccer field, including rooftops and parking lots. Cruising at high-speeds of 200 mph, Electra’s “blown lift” technology ensures safe, energy-efficient takeoff and landings at speeds below 30 mph. In this technology, the electric motor-driven propellers blow air over the entire span of the wing and its flaps. The single-pilot aircraft has eight electric motors powered by a combination of batteries and a small, quiet turbo-generator, allowing the batteries to be recharged mid-air.

With FAA certification planned in 2026, Electra’s first commercial product will serve urban and regional air mobility markets, sustainability-focused airline operations, “middle mile” cargo logistics, and air ambulance services.

Leveraging distributed hybrid-electric propulsion and blown lift, Electra’s unique electric ultra-short take-off and landing (eSTOL) aircraft takes off in less than 150 feet, but also offers nearly triple the payload capacity, an order of magnitude longer ranges, and less than half the operating costs of electric vertical takeoff and landing (eVTOL) alternatives.

Electra’s first propulsion system produces 150 kW (200 HP) of electrical power, consists of a small gas turbine and several custom components including a gearbox, generator, rectifier, control system, and software. Ground testing is planned this year followed by flight testing on the company’s technology demonstrator aircraft in 2022. The US Air Force has signed a contract with Electra for the same.

FLYING-V

Flying-V is a very futuristic concept designed with intense innovation, experimenting with the unusual wing and fuselage shape. The scale model of the Flying-V, claimed to be “the energy-efficient aircraft of the future”, flew for the first time in 2020 following extensive wind tunnel tests. In 2019, TU Delft and KLM had announced the start of the design of the Flying-V.

The Flying-V design of the aircraft integrates the passenger cabin, cargo hold and fuel tanks in the wings, creating a spectacular V-shape. Computer calculations have predicted that the improved aerodynamic shape and reduced weight of the aircraft will reduce fuel consumption by 20 per cent compared to today’s most advanced aircraft.

Experts tested a 22.5 kg and 3-meter scale model of the futuristic airplane, developed by researchers at Delft University of Technology in the Netherlands and partner Dutch airline KLM, to take the highly anticipated aircraft along its next developmental steps.

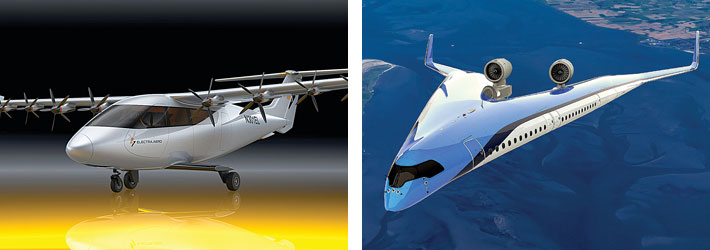

MAVERIC

One of the most futuristic aircraft, with a blended wing design that allows for new layouts and fuel storage is Airbus’ MAVERIC (Model Aircraft for Validation and Experimentation of Robust Innovative Controls). The European manufacturer revealed its “blended wing body” scale model technological demonstrator last year. The aircraft can carry up to 200 passengers in varying configurations due to the fuselage design, which is wide and shorter. The engines are also located at the back, offering unique ways to store and distribute hydrogen fuel. At 2 metres long and 3.2 metres wide, with a surface area of about 2.25m², MAVERIC comes with an aircraft design that has the potential to reduce fuel consumption by up to 20 per cent compared to current single-aisle aircraft. The “blended wing body” configuration also opens up new possibilities for propulsion systems type and integration, as well as a versatile cabin for a totally new on-board passenger experience.

BOOM’S OVERTURE SUPERSONIC

Boom’s supersonic adventures are highly awaited and look optimistic especially after the purchase done by United Airlines for Boom’s Overture. The company claims it to be the first airliner in a new era of enduring supersonic flight. Overture can cruise at 60,000 feet and aims to bring supersonic travel by 2029.

Boom’s XB-1 is also progressing, paving the way for mainstream supersonic travel by demonstrating the key technologies for safe and efficient high-speed flight.With a fuselage spanning nearly 71 feet in length, XB-1 is roughly 1/3 the scale of Overture and employs several different materials, including carbon composites, titanium, and aluminum. Each component is individually designed to balance strength, weight, and stability. At supersonic speed, the aircraft’s fuselage can withstand temperatures exceeding 300°F.

TRANSONIC TRUSS-BRACED WING (TTBW)

Boeing had unveiled a concept design for the future aircraft, the Boeing TTBW in 2019 and in 2030, the project is likely to take the skies. The aircraft is made in collaboration with NASA and reimagines wing design, and features a Transonic Truss-Braced Wing (TTBW), which is “far more aerodynamic, lightweight, and thinner than any current aircraft”.

The design and length of the wings is the most distinct feature of this aircraft. At 170 feet (51m), it’s far longer than any narrowbody. However, to compensate for the wingspan, the wings also have the ability to nearly fold into half, with support provided by the truss. By adjusting the wing sweep angle, the truss can carry lift more efficiently. The new configuration is designed to offer unprecedented aerodynamic efficiency while flying at Mach 0.80, which is consistent with the speed of many of today’s jetliners. Overall, the aircraft can deliver a 9 per cent reduction in fuel burn on a flight of up to 3,500 nautical miles.

VELIS ELECTRO

Velis Electro is world’s first electric powered airplane to receive a Type Certificate. The two-seater can be operated commercially and is fully approved for pilot training as well as other operations.

Featuring noise levels of only 60 dBa, Velis Electro is considerably quieter than other airplanes and produces no combustion gases at all. Velis Electro is a full-electric derivative of the proven Virus SW 121, which is already type certified by the European Union Aviation Safety Agency. Equipped with a Pipistrel type certified electric engine, the aircraft is developed with partners EMRAX and EMSISO, and Pipistrel’s three-bladed composite fixed pitch propeller. The 57.6kW liquid cooled electric engine provides power to the aircraft.

The power is delivered by 345 VDC electric system built around a liquid-cooled in-house developed high performance battery system, which includes two Pipistrel batteries connected in parallel, installed in a redundant 2-unit arrangement, total nominal capacity 24.8 kWh. Batteries can be charged via an onboard charging port using a Pipistrel electric charger. The battery pack is located in the nose of the airplane and the second behind the cabin, ensuring redundancy of the power source.

The liquid-cooling system consists of a radiator and two electrically driven pumps installed in series, located behind the rear battery pack. Two high power axial fans are installed behind the radiator in order to allow battery cooling during charging.

VOLOCONNECT

Volocopter’s newest eVTOL aircraft is the fixed-wing aircraft, VoloConnect works with two propulsion fans plus six electrical motors and rotors. The resulting lift-andcruise design aims to transport up to four passengers efficiently on routes of 100 km, with a maximum speed of 250 km/h and 180 km/h travel speed. With its lift-and-cruise design, natural stability, and high lift-to-drag ratio, the VoloConnect embodies nextlevel flight efficiency and is designed to work as an extension of our VoloCity urban air taxi services.

With two seats, and 18 rotors, the VoloCity air taxi is a technologically advanced electric aircraft with the ability to vertically take-off and land. The 18 motors inside VoloCity are powered by nine rechargeable batteries. The VoloCity has already received permits to fly in manned or unmanned configurations for pioneering test flights in Germany, Dubai, Helsinki, and Singapore.

The aviation industry partners are constantly coming together with innovations and working in collaboration towards a future that sees aviation meet cleaner sustainability standards and unimagined innovations with new designs for the airplanes of tomorrow. As the industry expands, these transitions will only see more experimentation and efficiency.