Digital Twins in Aerospace – A Paradigm Shift

Using a digital twin, engineers can accurately determine the life of structural components and this information can be used to improve performance, generate savings or increase operational flexibility

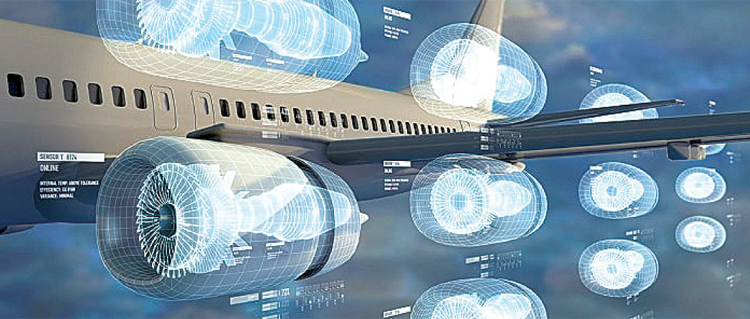

General Electric defines, “A Digital Twin is a dynamic digital representation of an industrial asset that enables better understanding and prediction of the performance of machines.” Advanced technologies are now blurring the lines between the physical and digital worlds and increasingly enabling aircraft operators to extend the life of their fleet. Using a digital twin, engineers can accurately determine the life of structural components and this information can then be used to improve performance, generate savings or increase operational flexibility.

USE CASES

Digital twin technology has been implemented for some time now across organisations. NASA has been using software replicas of its spacecraft for decades. It is believed that the successful return of the 1970 Apollo 13 mission after the oxygen tank exploded was orchestrated by the agency’s use of “mirrored systems” back on earth. The digital twin of the Lockheed Martin Block IIR GPS satellite, known as a SatSim, was built in 2018 for the Air Force Space and Missile Systems Center. The SatSim has enabled the vulnerability scans and penetration tests to be conducted on the whole GPS system, including the satellite, its ground control station and the radio frequency link between them. Digital twin technology also has been used to train AI to fly autonomous aircraft. AI pilots can get thousands of hours of flight time on a digital simulation in a fraction of that time and learn in days than what it takes, a human pilot, months to experience.

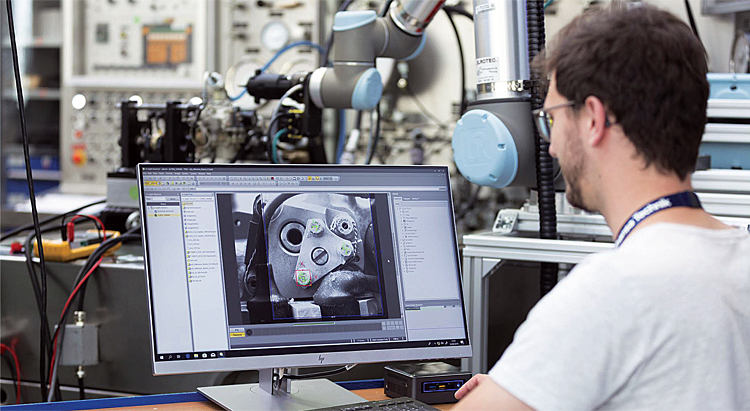

In the aerospace industry, expenditure on maintenance and repairs continues to increase in spite of aircrafts being built to last longer, more durable engines, and innovations in maintenance techniques. To address the shortcomings of conventional approaches, a paradigm shift of Digital twins is helping airlines bridge the gap between the physical and the digital worlds. Its ecosystem is created using ultra high-fidelity simulation software which comprises the sensor and measurement technologies, simulation and physics-based modelling, industrial Internet of Things, artificial intelligence, and machine learning. Aircraft line maintenance solutions are evolving rapidly in this new Avtar. Determining which types of maintenance is required during limited timeframes as task execution has always been a major challenge for the airline industry. Today’s aviation maintenance software solutions make aircraft maintenance management easy with digital twin software integration.

Modelling real-life systems and processes using digital twins, is becoming increasingly common in the aviation industry

GE has already built digital twin components for its GE60 Engine family and has helped develop the world’s first digital twin for an aircraft’s landing gear. Sensors placed on typical landing gear failure points, such as hydraulic pressure and brake temperature, provide real-time data to help predict early malfunctions or diagnose the remaining lifecycle of the landing gear.

At Boeing digital twins are used to design aircraft. Simulations are run that predict the performance of various aircraft components over the lifecycle. As a result, Boeing engineers can predict when components are expected to fail. According to the company they have achieved a 40 per cent improvement rate in the first-time quality of parts by using a digital twin. The company plans to digitise all of its engineering and development systems in the future and also plans to share this information with its supply chain.

Another use case being explored for Boeing aircraft is using a digital twin to achieve a perfect cargo load balance. For example, a Boeing 737-800 has a maximum cargo load of 80,000 kilograms but many planes fly with less cargo as weight figures are calculated manually. By using IoT sensors on a digital twin, a precise and yet safe cargo load can be determined thereby increasing cargo revenue per flight.

CONCEPT OF DIGITAL TWIN

Each asset has its own digital twin and operational details can be accessed throughout the asset’s life. By collecting and exploiting in-service data from the asset, enhanced predictions can be made regarding its condition to increase its operational value. During the fatigue analysis, a load spectrum is assumed and when combined with the appropriate material data, the life of a component can be determined. A digital twin approach, with appropriate sensors added to the aircraft, enables the load spectrum to be continually updated based on the actual loads the aircraft experiences and the resulting life prediction would be adjusted accordingly. If the aircraft experiences lower loads during service, more flights could be allowed, maintenance intervals could be extended or spare parts taken from retiring aircraft. The reverse is also true. No data on the details of the actual components, such as the detailed geometrical measurements, are required to support this approach. It could be referred to as a low-fidelity twin model characterised by a catalogue of the components in the aircraft and dynamic input data. Given current technology, the potential investment required for a low-fidelity approach, is minimal. There are still many challenges to overcome, including how to deal with missing data and verifying the robustness and airworthiness of the approach. Indeed, this type of digital twin is already in-use in civil aerospace by engine manufacturers for a variety of purposes.

If more data were available, a high-fidelity twin could be populated and that further improvements in aircraft structure life-optimisation would be possible. A high-fidelity twin adds detailed knowledge about the initial condition of the asset, such as detailed component geometry, mechanical assemblies and system calibration details, and updates these during the asset’s life from the collected data. A factory of the future using Industry 4.0 technology would be able to populate such a high-fidelity digital twin automatically during manufacture.

Modelling real-life systems and processes using digital twins is becoming increasingly common in the aviation industry. Until recently, the focus had been on improving production efficiency and performance in engineering processes, from parts manufacturing to aircraft design. With the technology’s rapid evolution, the potential applications are growing: fully-functional digital twins of entire airports could be just a few years away. SITA Lab is currently working on a fully functional digital twin of a US East Coast airport. When digital twins become standard, airports will have an unprecedented database to draw from. Airlines and airports could pool their digital twin data across a shared network to optimise operational communications on a national or global scale. The digital twin of digital twins’ concept will take time to evolve, vendors will start to compete not just on who has the best products, but who also has the most competent digital twins of those products.

TECHNOLOGY DRIVING THE TWINS

Advances in digital twin capabilities have been driven by four key technologies:

- IoT & Big Data: The proliferation of smart sensors on assets or components combined with connected systems allows organisations to gain insights into live operational performance;

- Advanced analytics: Through machine learning, data can be used to predict and simulate the future condition of assets;

- Computing power: Cloud-based technology vastly improves the affordability and availability of the computing power required to run large-scale digital twin models;

- Accessibility: Previously a digital twin may have been locked into the control room of a factory or an organisation, but now data can be accessed anywhere from mobile devices.

Essentially, a digital twin software is used to create a virtual 3D model of the asset. This model can go through a range of simulated environments that the asset is likely to encounter. The flow of information from raw data to high-level understanding is propelled by data fusion techniques – sensor-to-sensor, sensor-to-model, and model-to-model fusion – which are implemented, and will function, at different levels. A digital twin is designed for one or more important systems, including airframe, propulsion & energy storage, life support, avionics, and thermal protection. Data is critical for creating an effective digital twin. If data pertaining to the initial condition of the asset is available (system calibration details, component geometry, mechanical assemblies, etc.), it is possible to create a high-fidelity twin for the purpose of quality improvement.

WIDE MRO CANVAS

Digital twins can work in different situations, applications and processes depending on the context of the organisation. Component manufacturers, for example, are primarily focused on individual components, while engine OEMs are focussed on the engine as an entire asset. Heavy/base maintenance inspectors and regulators focus more on overall maintenance business processes and standards, and this continues through to line maintenance providers who primarily assess MRO data and the airline/operator who in turn want to form a digital twin of the entire aircraft. OEMs and MROs are ideally placed to harness the ROI and benefits of digital twin technology to optimise their service offerings and business performance. But to effectively implement a digital twin strategy requires the support of flexible enterprise software geared towards data-driven decision-making.

CRYSTAL BALL GAZE

Digital twins will emerge in the near future as one of the key IT tools in manufacturing industries, revolutionise product development and product testing in a wide variety of areas. Therefore, in the future almost every manufactured product could have its own digital twin as long as it somehow generates data which can be captured and analysed. This concept is known as a ‘digital triplet’ and will represent the next stage of evolution of the digital twin. For example, instead of having just one digital twin of a new aircraft for development purposes, the company will have a unique digital model for every aircraft it makes. These individual models can feed information from connected sensors in real time and AI analysis can be applied to make real time predictions about the product life cycle, predictive maintenance etc. Although achieving fullyfunctional digital twins will demand a premeditated and persistent effort to reap the rewards, it will be game-changing and can deliver incredible results.