Engines For Wide-Body Aircraft

As passengers become more discerning, attention of the airlines is on safety, comfort, innovation, sustainability and responsible flying while keeping an eye on costs efficiencies

Year 2020 is coming to an end and what a year it was, especially for the global commercial aviation sector. The upheaval in the aviation sector due to the Covid-19 pandemic and the subsequent grounding of all flights worldwide, has forced the airlines and aircraft manufacturers to rework their business models and focus on “Operational and Financial efficiencies” to achieve growth and sustainability.

OPERATIONAL AND FINANCIAL EFFICIENCIES

New aircraft deployment has to have a healthy mix of wide-body aircrafts that can free up a substantial chunk of narrow-body fleets which can then be used successfully on newly opened regional routes. In addition, wide-body aircraft offer airlines the opportunity to offer better customer experience through better valueadded services and more deck space for airlines to implement incabin features – something that is becoming a deciding factor in passengers’ airline choices.

The ability to carry higher passenger volumes with wide-body aircraft allows airlines to easily connect the increasing number of regional aviation networks and hubs. Also, low-cost domestic carriers get traffic into their metro hubs from where the wide-body planes offer connectivity to the final destinations. Wide-bodies on domestic routes provide a high yield option for airlines enabling them to carry more passengers to airports with limited slots.

RESPONSIBLE AND SUSTAINABLE FLYING

Improvements in operational efficiencies must go hand-in-hand with investing in more fuel-efficient aircrafts to balance growth with environmental commitments. Decades of technological advancements have made aircraft engines more fuel-efficient and any savings in fuel cost reduces operational cost as well as carbon emissions. Larger and wider aircrafts will begin to benefit from novel designs that will further improve efficiency through management of aircraft drag and distributing propulsion in new ways.

A competitive environment demands that operating costs be kept low. Improved fuel-efficiency not only reduces costs for airlines, and thus passengers, but it also contributes significantly to reducing the aerospace industry’s environmental footprint. We look at the Engine manufacturers with their engine options that power the wide-body aircraft.

GENERAL ELECTRIC (GE)

With more than 33,000 engines in service, GE is a world leader in jet engine manufacturing, offering products for many of the best-selling commercial airframes. Each one of GE’s commercial engines is a leader in its class for performance, reliability and cost of ownership.

The GE90 – A technology pioneer: The GE90 engine family powers all Boeing 777 models. It is the exclusive powerplant on the Boeing 777-300ER, -200LR, and Freighter. The engine has accumulated nearly 100 million flight hours and 14 million cycles since entering service.

With the GE90, GE introduced the composite fan blade—the first-ever in commercial aviation. The GE90 fan blade’s uniquely curved design makes it larger, lighter and more aerodynamic than traditional titanium blades for reduced engine weight and lower fuel burn. Plus, the aerodynamic design allows the GE90 fan blade to pull large amounts of air into the engine, making it quieter and more efficient while generating unrivaled thrust.

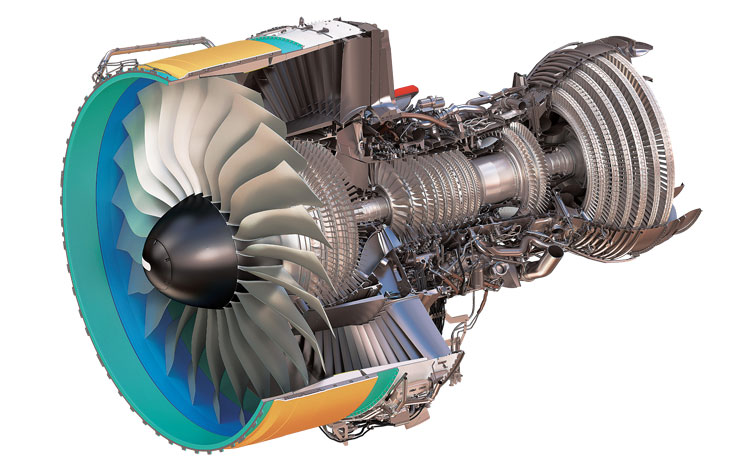

GE9X – The world’s next great engine: The GE9X is the world’s largest and most powerful commercial aircraft engine. It incorporates GE’s most advanced technologies that have been developed over the last decade to make it the most fuel-efficient engine in its class while also delivering unmatched performance. The GE9X is the sole-sourced engine for the Boeing 777X family.

With the most extensive technology maturation programme in the history of GE Aviation, the GE9X engine delivers world-class reliability and performance at service entry. A blend of evolutionary and revolutionary designs enables the GE9X to be the most fuel-efficient jet engine GE has ever produced on a per-poundsof- thrust basis. It’s designed to deliver a 10 per cent improved aircraft fuel burn versus the GE90-115B-powered 777-300ER and a 5 per cent improved specific fuel consumption versus any twin-aisle engine available, plus achieve an approximate 10:1 bypass ratio, a 60:1 overall pressure ratio and margin to Stage 5 noise limits.

GEnx – The fastest selling engine: The GEnx is the fastestselling, high-thrust jet engine in GE Aviation history with more than 2,700-plus engines in-service and on order. GEnx is the bestselling engine on the 787 Dreamliner in addition to powering the four-engine Boeing 747-8. Based on proven GE90 architecture, the GEnx engine offers up to 15 per cent improved fuel efficiency and 15 per cent less CO2 compared to GE’s CF6 engine. The GEnx engine represents a giant leap forward in propulsion technology, using the latest materials and design processes to reduce weight, improve performance and deliver a more fuel-efficient commercial aircraft engine.

Key to GEnx engine’s performance are its high pressure compressor, lean-burning combustor and lightweight durable composite materials, including the world’s first composite fan case and fan blades for commercial aircraft. With the highest pressure ratio compressor in commercial service today, the GEnx has the best fuel efficiency in its thrust class, enabling it to power many of the longest routes. These leading-edge technologies and the engine’s elegant architecture bring in high operational reliability, excellent utilization rate and route flexibility for more flights per year and more revenue for airlines.

The CF6 engine family: Cornerstone of the widebody engine aircraft business.

For 45 years, the CF6 engine family has established an impressive operational record. CF6 engines have compiled nearly 430 million flight hours since they first entered commercial revenue service in 1971. Certified to power more than 13 different aircraft types, the CF6 has accumulated more than 115 million flight cycles in service.

The Qantas flight from Dallas to Brisbane is one of the world’s longest nonstop commercial flights, and GE’s CF6 engines help make it possible. The flight is powered by four GE CF6 enginesand covers nearly 8,500 miles. The CF6-80A and -80C2 engines are known for their high reliability, and this was evident during extended twin operations (ETOPS) testing. Both engines received 180-minute ETOPS approval on the Boeing 767, and the CF6-80C2 engine received 138-minute ETOPS approval on the A300 and A310 aircraft that allowed twin-engine aircraft operations over large bodies of water.

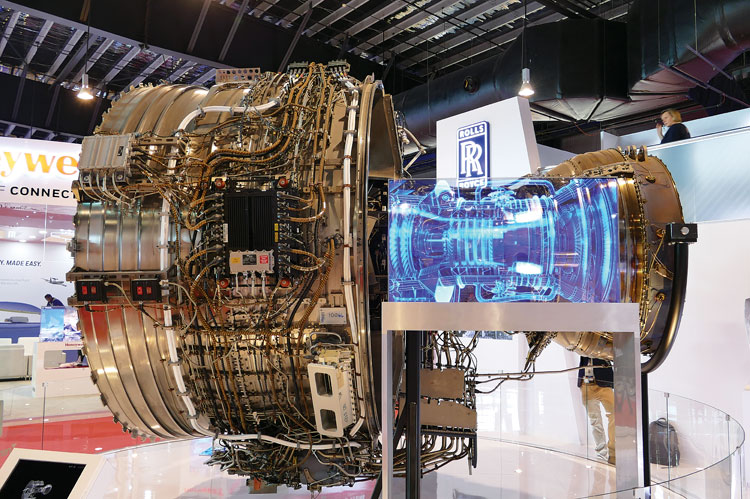

ROLLS-ROYCE

For nearly three decades, Rolls-Royce family of turbofan aircraft engines have continued to push the boundaries of what is possible, as each new model sets new performance benchmarks for commercial aviation. All told, they’ve earned more than 100 million flying hours. Members of the Trent engine family are now in service on the Airbus A330, A340, A350, and A380, as well as the Boeing 777 and 787 Dreamliner.

The Trent family has revolutionised travel, enabling operators to achieve new possibilities in doing so, from pioneering new routes, to adapting existing routes, allowing passengers to be connected more efficiently than ever before.

Every generation of Trent has successfully proven itself, delivering the versatility needed by customers to operate effectively and efficiently across the globe. The engine family also demonstrates capability to operate across a wide range of operational conditions, from short domestic operations, through to ultra-long routes, including powering the longest passenger flight in the world.

Trent family powers aircraft to over 700 destinations and has demonstrated the capability to operate in a wide range of environments, such as the hot and harsh airports of the Middle East to the sub-zero temperatures of destinations in the Nordics. From the first Trent operator, Cathay Pacific, the seven-strong engine family is now in service with over 150 operators, serving destinations in over 185 countries.

Trent XWB – Ultra-long-range flying machine: How the ‘Trent’ created ‘a new possible’ when it became the only engine family to power the world’s longest commercial flight... To only then do it again, with a twin-engine aircraft.

Trent 700 – Best engine for the Airbus A330: Trent 700 powers more variants of the Airbus A330 than any other engine. As the only engine specifically designed for the aircraft, it has both outstanding efficiency and reliability, but also demonstrated capability and versatility to power a diverse range of aircraft and missions. The engine design is built upon the success of the unique Rolls-Royce three-shaft engine architecture and the latest technology. It delivers the best balance of attributes to achieve the maximum capability and efficiency on the A330. The Trent 700 is the engine of choice on the Airbus A330 family with over 800 aircraft in service.

Trent 1000 – All the thrust you require: The Trent 1000 delivers the power required for all members of the Boeing 787 Dreamliner family, the 787-8, 787-9 and 787-10. Whether it’s hot or high airports, short or long routes in your network - if the 787 can fly it; the Trent 1000 can power it.

PRATT & WHITNEY

Pratt & Whitney, a unit of Raytheon Technologies, is a world leader in the design, manufacture and service of aircraft engines and auxiliary power units. Their large commercial engines power nearly 30 per cent of the world’s mainline passenger aircraft fleet. The fleet of commercial engines has logged more than 1 billion hours of flight, powering the narrowand wide-body aircraft that fly both passengers and cargo around the world. Their patented technology has changed the boundaries of time and shortened the distance between people and places.

PW4000 family of high-thrust engines: Airplanes powered by this engine are Boeing 747, Boeing 767, MD-11, Airbus A300 and Airbus A310. The engine provide airlines with excellent operational flexibility and high reliability. Advanced, service-proven technologies, such as single-crystal superalloy materials and its Full-Authority Digital Electronic Control (FADEC), contribute to superior fuel economy and reliability. The engine’s benefits are further enhanced by excellent performance retention, long onwing times and low maintenance costs.

The PW4000’s noise and emissions parameters are lower than levels required for all current and anticipated emissions and noise regulations. For a further reduction in emissions, Pratt & Whitney’s TALON (Technology for Advanced Low NOx) combustor technology is now available for the PW4000.

Since entering revenue service in 1987, Pratt & Whitney has delivered more than 2,500 PW4000-94” engines that have collectively logged more than 120 million dependable flight hours on commercial aircraft around the world.

Pratt & Whitney has taken its successful PW4000 100-inch engine for the Airbus A330 to new heights with the introduction of the PW4170 Advantage70™ programme.

Developed specifically for the Airbus A330 twinjet and introduced in 1994, the PW4000 100-inch fan engine has thrust capability from 64,500 to 70,000 pounds at take-off. Pratt & Whitney supplies A330 customers the entire propulsion system - engine, nacelle, thrust reverser and accessories. This, along with superb service reliability, excellent performance retention and low cost of ownership, make the PW4000 100-inch engine an outstanding value.

The PW4000 112-inch engine, an ultra-high-thrust model covering the 74,000 to 90,000 pound-thrust class, is the reliability, experience and Extended-range Twin-engine Operations (ETOPS) leader for the 777 aircraft, providing the best customer value.

ENGINE ALLIANCE: PRATT & WHITNEY AND GENERAL ELECTRIC JOINT VENTURE

The Engine Alliance, a 50/50 joint venture between General Electric Aviation and Pratt & Whitney, was established in 1996 to develop, manufacture, sell and support a family of advanced technology engines for new high-capacity, long-range aircraft. The result is the GP7200, a twin spool axial flow turbofan that delivers 70,000 pounds of thrust for the Airbus A380.

The GP7200 – Powering the A380: The GP7200 is derived from two of the most successful wide body engine programmes in aviation history—the PW4000 and GE90 families. The engine benefits from each programmes’ latest proven technologies and incorporates lessons learned from more than 25 million flight hours of safe operation on both engines. The GP7200 entered service in 2008 with the world’s largest A380 fleet, Emirates. The first GP7200-powered A380 was delivered to Air France in 2009. Since entering service, the GP7200 has achieved a 99.9 per cent departure reliability rating without experiencing a single in-flight shutdown.

Globally, commercial aviation is at the cusp of major technological advancements. Larger and wider aircrafts will begin to benefit from novel designs that will further improve efficiency through management of aircraft drag and distributing propulsion in new ways.