Pratt & Whitney Engines in Indian Skies

In India, the Pratt & Whitney engines have powered over 960,000 flight hours and saved more than 52 million gallons of fuel and avoided 510,000 tonne of carbon emission to date

Pratt & Whitney (P&W) is part of United Technologies Corporation, one of the world’s largest suppliers of aerospace products, with an established presence in India. The company has played a significant role in India’s aviation growth story and its global product suite includes commercial engines, military engines, small jet and turboprop engines and other general, regional and civilian powered flight engines.

Pratt & Whitney’s PW2040 commercial engine, which powers the Boeing 757 has proven itself as a world-class, dependable engine. The PW1100G-JM engine for Airbus A320neo family of aircraft and the PW1500G engine for the Bombardier C Series are certified and in passenger service with operators across the globe since January 2016. This engine is meeting performance targets pertaining to fuel efficiency, noise reduction and lower NOx emissions.

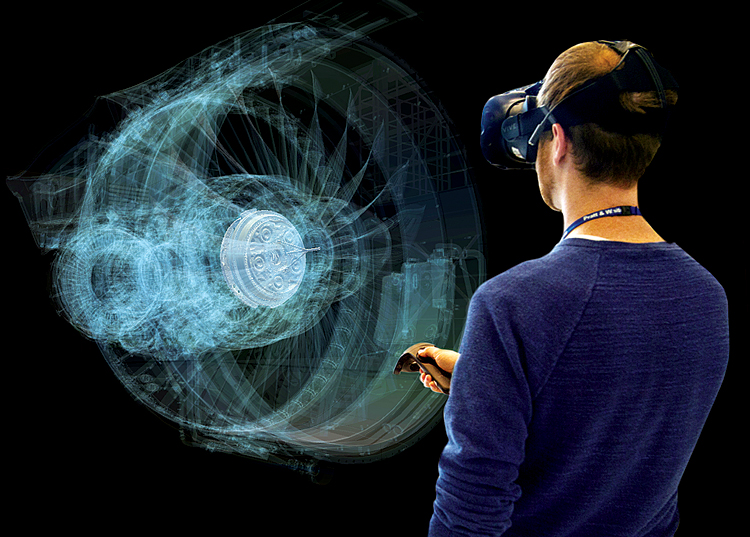

The Pratt & Whitney PW1000G is a high-bypass geared turbofan engine family. The project was previously known as the Geared Turbofan (GTF), and originally the Advanced Technology Fan Integrator (ATFI). The GTF engine, with its revolutionary geared fan technology, is transforming aviation by delivering gamechanging economic and environmental performance. The GTF engine powers five aircraft platforms, with the Airbus A220, the Airbus A320neo family and Embraer E190-E2 already in commercial service. The Mitsubishi Regional Jet (MRJ) and Irkut MC-21 are currently undergoing flight testing. The GTF engine has met all performance specifications since entry into service. For example, the GTF-powered A320neo has achieved a 16 per cent reduction in fuel consumption, a 75 per cent reduction in noise footprint and a 50 per cent reduction in nitrogen oxide emissions.

Pratt & Whitney is an important player in the Indian aviation space. Today, P&W and International Aero Engines (IAE) together power more than 500 aircraft in India today including more than 43 per cent of passenger aircraft in the country. P&W has been selected to power at least 31 per cent of future passenger aircraft in India, with another 37 per cent of aircraft awaiting engine selection. The neo fleet of planes from Airbus and the MAX family of Boeing have become popular among airlines recently due to the prime attraction of fuel savings, as much as 16 per cent. In India, the P&W engines have powered over 960,000 flight hours and saved more than 52 million gallons of fuel and avoided 510,000 tonne of carbon emission to date, the engine maker has claimed.

SAFETY CONCERNS OF PW1100 SERIES

In March 2018, the DGCA had expressed concern with PW1100 engines, grounding both IndiGo and GoAir aircraft with the said engine, affected by faulty compressor seals. A month earlier, in February 2018, both the European Aviation Safety Agency (EASA) and the US Federal Aviation Association (FAA) issued Airworthiness Directives (AD). The EASA’s emergency AD for Airbus A320 and A-321 aircraft indicated several occurrences of engine in-flight shutdown and rejected take-off, while the FAA’s warning cited a “knife edge seal failure” in the engine that could lead to an engine stall “and consequent in-flight shutdown and rejected take-offs”.

Despite these challenges, Airbus, continued to show faith in the engines. Phillipe Mhun, Chief Programmes & Services Officer, Airbus in a conference said, “I just want to highlight something which is the reality of the industry. Whenever we are developing new aircraft or new engine, it comes with its set of maturity challenges and this is where we are with the engine manufacturers. I can tell you that they are providing very sound, robust answer to the early issues that we experienced in the field. I can tell you so that, here we are not talking about safety concerns, safety is ensured and this is what our chief engineering team are really delivering. We are keeping updated both the airlines and the authorities about the progress in terms of technical standard of the engine and this is where we are. A major step in terms of reliability improvement coming in the summer is called ‘Block D’. We are prioritising some of the ETOPs. Operators to get the improvement on boarded biweekly on their aircraft... and this is where we are. Just have a look at the previous two programmes in terms of engines and you will see that it comes with its set of challenges, and this is where the industry has a lot of maturity and I can tell you that both our engines partners are treating it very professionally. Today the A320NEO operational reliability is higher this year. That’s a given”.

AVIATION REGULATOR DGCA HAD ISSUED A PUBLIC NOTICE HIGHLIGHTING A DETAILED ACTION-TAKEN EXERCISE TO ADDRESS THE ISSUES. “DGCA HAS ENSURED THAT SAFETY OF AIRCRAFT OPERATIONS IS NOT COMPROMISED AT ANY STAGE,” IT SAID.

This statement was reinforced by Christian Scherer, Chief Commercial Officer, Airbus who said, “It is true... The trend lines are very positive in India and elsewhere and to Phillipe’s point on the NEO engines introduction, if you look at the statistics, they are better than introduction of the previous generation engines”.

The company was in the spotlight in the Indian aviation space since 2016 when India’s largest airline IndiGo started facing delivery delays in A320neo aircraft amid issues related to cooling down and start-up time of the engine, reliability, combustion chamber lining, oil seal and fan blades. In fact, in 2018, India’s aviation regulator, the DGCA, grounded as many as 14 Airbus A320neos following warning of a potential in-flight shutdown in a sub-category of its Pratt & Whitney engines. This year, the company along with other stakeholders found themselves, in a tense situation again when the Ministry of Civil Aviation called for a review meeting following a series of engine glitches resulting in in-flight shutdown. However, the engine maker maintains that there are no safety concerns with its engines. Aviation regulator Directorate General of Civil Aviation (DGCA) had issued a public notice highlighting a detailed action-taken exercise to address the issues. “DGCA has ensured that safety of aircraft operations is not compromised at any stage,” it said.

IndiGo’s Chief Operating Officer Wolfgang Prock-Schauer said that the airline saw a strong improving trend in the performance of the Pratt & Whitney engines with the in-flight shutdown rate being reduced by half which is very much below the international standards. “We are confident that all the measures taken by Pratt and Whitney are showing results. For most issues resolutions have been found and implemented,” he added. He said the airline had received safety clearance from the US Federal Aviation Administration to continue operating the engines and that they were “well within the [safety] limits”. He revealed that for IndiGo’s PW1100Gs, in-flight engine shutdowns were occurring at a rate of 0.02, as compared with the FAA’s limit of 0.05. “The situation is completely under control.”

Delhi-based low-cost airline IndiGo also confirmed that it is studying the feasibility of including wide-body aircraft in its fleet but is unlikely to place an order in the near future. Ronojoy Dutta, CEO, said “For wide-body there is nothing imminent. Are we studying it? Absolutely! But are we about to place an order or do we see something happening in the near future? No.”

“IT IS TRUE... THE TREND LINES ARE VERY POSITIVE IN INDIA AND ELSEWHERE AND ON THE NEO ENGINES INTRODUCTION, IF YOU LOOK AT THE STATISTICS, THEY ARE BETTER THAN INTRODUCTION OF THE PREVIOUS GENERATION ENGINES”, CHRISTIAN SCHERER, CHIEF COMMERCIAL OFFICER, AIRBUS

Pratt & Whitney continues to invest in resolving the issues in its new aircraft engines – the lead market for which is India even after crossing one million hours of service, typically considered a significant period for identifying and resolving problems with a new product. The GTF engines, powering 460 planes in the world and 114 in India, have crossed 2.5 million hours of service. P&W maintains that the GTF engine has demonstrated 99.94 per cent dispatch reliability in the past 12 months in India as against 99.87 per cent dispatch reliability for the same period globally. In India, GTF engines power 280 flights transporting 44,000 passengers per day. Globally, 1,900 GTF powered flights transport 2,88,000 passengers per day.

P&W HANDHOLDING IN INDIA AVIATION GROWTH

With the company aggressively focusing on India, some of the handholding initiatives in the Indian aviation sector undertaken by Pratt & Whitney that need to be highlighted are:

- Customer Training Centre, Hyderabad – Received certification of its training centre by the DGCA in April 2017 to provide DGCA CAR147-approved training to aircraft engineers and technicians from Pratt & Whitney’s airline customers in the region. In May 2019, Pratt & Whitney Customer Training Center in India surpassed 5000 Student Days of Training

- EngineWise service brand — Services designed to provide more predictive and responsive solutions to customers

- PW1100G the newly stationed GTF engine at the training centre designed to meet the aggressive emissions requirements and to run a higher level of cooling technology

- Pratt & Whitney Canada signed a Fleet Management Programme maintenance contract with IndiGo for PW127M to power the airline’s new fleet of ATR72-600 aircraft serving regional routes in India.

- The Saras, produced by the India aerospace industry, will be powered by two Pratt & Whitney Canada PT6A-67A turboprop engines rated at 895kW of output power each.