Get More from Every Drop!

Airlines have their own incentive to increase fuel efficiency and reduce emissions, because each tonne of CO2 they avoid adding to the atmosphere, represents significant saving on fuel cost

The fleet database of CAPA – Centre for Aviation indicates that there were 31,600 commercial aircraft in service worldwide at the end of 2017, an increase of 4.1 per cent over 2016. And based on a firm order backlog of over 17,000 planes, the number will continue to rise. The long-term forecast is even more bullish. In July this year, Boeing estimated that 42,730 new jets will be needed over the next 20 years to cater for the rising demand especially from China and India.

While such glowing predictions bring joy to the airline industry, they are unlikely to thrill environmentalists. According to the International Air Transport Association (IATA), civil aviation as a whole added around 859 million tonnes of carbon dioxide (CO2) to the atmosphere in 2017. This is a small fraction (a little over two per cent) of the 36 billion tonnes of annual anthropogenic carbon emissions, but aviation greenhouse gases (GHG) have an enhanced impact on the atmosphere because they are released at high altitude. And although the fuel efficiency of jets has improved significantly over the years, emissions are steadily rising because of aviation’s expanding footprint. Therefore, the industry has set itself an ambitious target to slash net carbon emissions to half the level in 2005 level by the year 2050. This requires huge investments and a step change in engine technology.

RAISE EFICIENCY, LOWER EMISSIONS

The jet age that began with the de Havilland Comet in 1952, is still going strong. While most surface modes of transportation are becoming increasingly dependent on vehicles driven by electrical power, only very small aircraft are powered by electricity. That is because only jet engines have enough power to propel large airliners through the skies at high speeds. But they also spew kerosene fumes into the atmosphere.

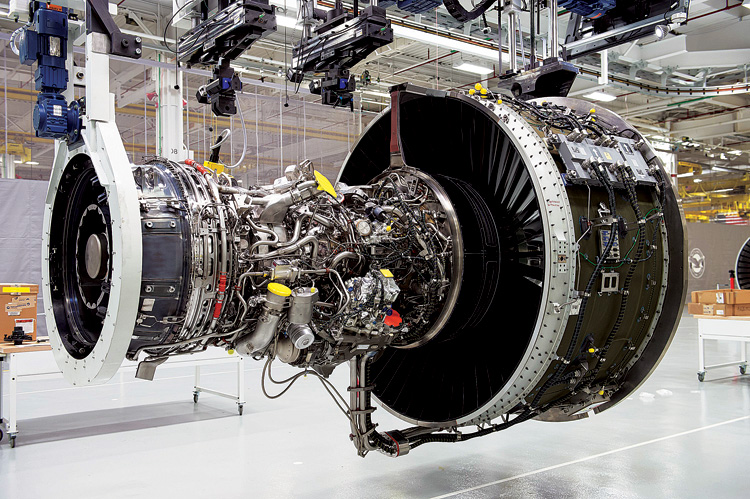

The aviation industry is keen to boost fuel efficiency and consequently curb emissions. Yet attempts to switch to biofuels are well behind target and instead have intensified environmental problems such as rampant deforestation and changes in land use. Manufacturers such as Airbus and Boeing are spending huge sums to reduce weight through redesign and use of new lightweight materials in an effort to make airframes more efficient. But the best medium-term route to cleaner skies is probably through advances in engine technology. That is why new fuelefficient engines such as Pratt & Whitney’s PurePower PW1000G and CFM International’s Leading Edge Aviation Propulsion-1 (LEAP-1) turbofan are selling like hot cake.

LEAPING AHEAD OF PUREPOWER

Once gas-guzzling turbojets evolved into fuel-efficient turbofans in the 1960s, it took only a short time for turbofans to power practically every commercial jet. Modern turbofans have high bypass ratios of up to 9:1. This is an important measure of efficiency as it means that nine times as much air flows around the engine core as through it. But they consequently require larger intakes to accommodate bigger and better fans and the longer fan blades mean their tips are turning at close to the speed of sound where potentially dangerous vibrations could set in.

That is why Pratt & Whitney spent about 30 years and over $10 billion to develop its PurePower range of high-bypass geared turbofan engines – the exclusive engine for the Airbus A220, Mitsubishi Regional Jet (MRJ) and Embraer’s E-Jet E2 family. The company offered this engine as an option for the Airbus A320neo and Irkut MC-21. The PW1100G that powers the A320neo entered commercial service with Lufthansa in January 2016.

PurePower engines use a sophisticated gearbox attached to the shaft to turn the compressor fan and low-pressure turbine each at their most efficient speed. This permits slower and larger fans (81 inches diameter on the A320neo) and an increased bypass ratio of 12:1. As compared to the older A320ceo, the A320neo reduces fuel burn and CO2 emissions by 16 per cent, generates 75 per cent less noise and emits 60 per cent less nitrogen oxides (NOx). The downside includes greater engine weight and aerodynamic drag, as well as increased complexity of the engine which heightens the risk of failure, as IndiGo’s and GoAir’s troubles with their new Airbus A320neo airliners starkly highlight.

THE AVIATION INDUSTRY IS KEEN TO BOOST FUEL EFFICIENCY AND CONSEQUENTLY CURB EMISSIONS. YET ATTEMPTS TO SWITCH TO BIOFUELS ARE WELL BEHIND TARGET.

So why not simply improve the tried and tested turbofan as much as possible? That is exactly what CFM International has done with its LEAP-1 family of high-bypass turbofan engines. LEAP-1 uses advanced design techniques, lightweight composite materials, coatings, combustion and cooling technology as also improved integration between the engine and airframe to boost efficiency. In the process, it provides 15 per cent lower fuel burn compared with its predecessor engine, the iconic CFM56-5B. The LEAP-1A entered commercial service in August 2016 when Turkish budget carrier Pegasus flew the first Airbus A320neo. The LEAP-1B also entered revenue service in May 2017 on the Boeing 737 MAX platform while the Chinese Comac C919 powered by the LEAP-1C is in the flight test phase. These two technological marvels, the LEAP-1 and the PurePower engines, are set to power single-aisle airliners – the vast bulk of the global commercial fleet – for a couple of decades or more. While the LEAP-1 has attracted more than 14,270 orders and commitments, the PurePower engine has secured orders of over 8,000. But although the evolutionary design process has delivered satisfactory results so far, what is needed is a revolutionary increase in fuel efficiency.

REVOLUTION IN THE AIR?

The traditional aeronautical design process has a significant pitfall. Airframe designers build aerodynamically efficient structures and are not unduly concerned about the engine. On the other hand, engine technologists independently build a power plant potentially compatible with a variety of airframes. Overall efficiency inevitably suffers in the bargain. But the tube-and-wing arrangement with twin turbofans slung under-wing, is now nearing its limits of exploitation and aviation technologists feel compelled to switch to integrated engine-airframe design.

In 2008, Aurora Flight Sciences, the Massachusetts Institute of Technology (MIT) and Pratt & Whitney began a NASA-sponsored effort to revolutionise future aircraft. The Aurora D8 will be similar in size to the Airbus A-320/Boeing 737, but will feature a wide “double-bubble” fuselage to generate increased lift. This means smaller wings, a lighter landing gear and a reduced tail. Consequently, it will need engines that are smaller, are of lower weight and and carry less fuel. Unlike the conventional engines that are slung under the wing, the D8 will have twin jets integrated with the fuselage, making for a clean high-aspect-ratio wing with low drag. The large fan will have a much higher bypass ratio of 20:1. Further, since the engines will be mounted at the rear, they will reenergise the slow-moving boundary layer flow over the fuselage and promote Boundary Layer Ingestion (BLI), thus increasing aerodynamic efficiency. Indeed, every part of the airframe and engine will be meticulously configured to maximise efficiency and minimise operating costs. If various technological challenges are successfully overcome, the D8 may offer huge benefits such as 71 per cent lower fuel burn and emissions, Effective Perceived Noise level in decibels (EPNdB) of 60, and 87 per cent reduction in landing and takeoff emissions of NOx as compared to current single-aisle aircraft such as the A-320 or the Boeing 737.

FOR A CLEAN SKY

Meanwhile in Europe, Clean Sky stands out. Clean Sky, a joint undertaking of the European Commission and the European aeronautics industry, aims to get the most out of every drop of fuel for every category of aircraft. Accordingly, it is studying radical new approaches, new shapes and new aircraft geometries for large passenger aircraft, regional aircraft, rotorcraft and small air transport aircraft. Clean Sky 1 exceeded its ambitious targets set in 2007 and Clean Sky 2 is now in full swing.

Safran’s Open Rotor demonstrator is a key part of Clean Sky’s plans to develop a more fuel-efficient propulsion system for airliners by around 2025. It involves studying novel aerodynamic and material technologies to improve the inherently noisy propfan engine. The next generation propfan is actually a gas turbine driving two high-speed unshrouded fans turning in opposite directions. Initial testing promises 15 per cent improvement in fuel burn and emissions over the CFM LEAP-1 engine, with comparable noise levels. Rolls-Royce is also developing propfans.

The good news is that apart from green pressures, airlines have their own incentive to increase fuel efficiency and reduce emissions, because each tonne of CO2 they avoid adding to the atmosphere, currently represents a direct saving on fuel cost of approximately $225. In an era of rising oil prices, fuel economy becomes even more important. In India for instance, the price of fuel, which accounts for 35 to 40 per cent of an airline’s cost of operations, has surged by nearly 30 per cent over the past year and may rise even further. Hence, there is good reason to make every drop count using improved engine technology.