Powerful Engines

The world’s top jet engine makers are indeed investing heavily in research and development efforts to rake in from the mega orders that are being placed globally by airlines

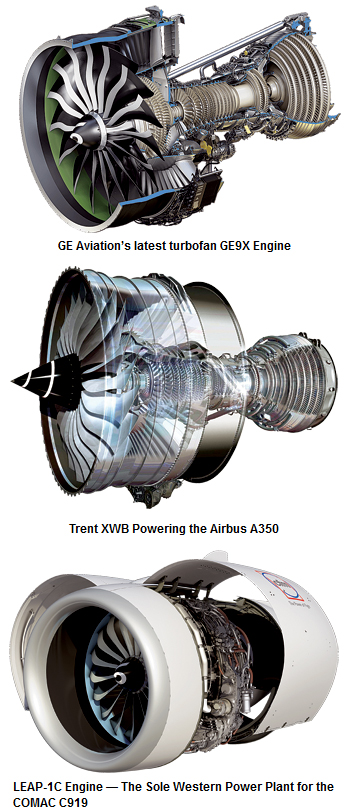

At the 2013 Paris Air Show, GE Aviation unveiled the latest in its powerful class of turbofan engines — the GE9X, said to be the world’s largest and next great engine. The GE9X is the most fuel-efficient engine GE has ever produced on a per-pounds-of-thrust basis.

It is claimed to be the largest jet engine ever built. The GE9X, with about 13 feet in diameter, is wider than the fuselage of a Boeing 737. GE has designed this mega engine specifically for the Boeing 777X wide-body airliner expected to take flight in 2020. The engine uses 3D printed components, composite materials and redesigned fan blades and air routing to deliver a staggering 10 per cent increase in fuel-efficiency without sacrificing power or reliability. A blend of evolutionary and revolutionary designs will it deliver a 10 per cent improved aircraft fuel burn versus the GE90-115B powered 777-300ER and a 5 per cent improved specific fuel consumption versus any twin-aisle engine available, plus achieve an approximate 10:1 bypass ration, a 60:1 overall pressure ratio and margin to Stage 5 noise limits.

The GE9X will be one of GE’s latest ecomagination qualified products. It will feature the same world-class reliability as the GE90-115B, with noise and NOx emissions well below anticipated regulation standards. Environmental performance highlights include: The quietest engine ever produced by GE 8db margin to Stage 5 and the lowest NOx emissions from a GE engine approximately 30 per cent margin to CAEP 8.

GE said it has fired the first GE9X engine more than seven months ahead of a typical programme schedule on its testing grounds in Peebles, Ohio, to ensure ample time to validate and mature its design before entry into service on the new Boeing 777X aircraft. GE Aviation invested $10 million to prepare its Peebles Testing Operation for the GE9X.

Designed to be the largest and most efficient ever made, the low pressure turbine testing is built with state-of-the-art materials and processes that are tested, refined and tested again at Massa, Italy.

Addictive manufacturing popularly known as 3D printing, essentially grows parts from the ground up and allows engineers to design complex internal shapes that were previously impossible to achieve. “These tunnels and caves are a closely guarded secret,” said GE Aviation spokesman Rick Kennedy. “They determine how the fuel moves through the nozzle and sprays inside the combustion chamber.”

Although this is the first time the company fired up the whole engine, it’s been testing individual components and systems for four years. “Due to the significant amount of new technologies in the GE9X, we planned the testing programme differently,” says GE9X programme leader Chuck Jackson. “The early testing informed the design and manufacturing and allowed us to freeze the product definition and test the total engine as soon as possible.”

Generate 1,00,000 Pounds of Thrust

The GE9X was designed to generate 1,00,000 pounds of thrust. (One space shuttle main engine produces 3,75,000 pounds.) While that may seem like a lot, the world record belongs to the engine’s predecessor, the GE90-115B, which generated 1,27,500 pounds of thrust.

When Boeing decided to build the 777X jet, the next-generation version of the 777 jet, it asked GE to develop an engine to power it. GE Aviation, which is the exclusive engine maker for the 777X, has received orders for more than 700 GE9X engines valued at $29 billion (list price) from airlines including Emirates, Lufthansa, Etihad Airways, Qatar Airways and Cathay Pacific.

Rolls-Royce’s Trent XWB Going Strong

For many, January 15, 2015, will live long in the memory. As the world’s media gathered alongside airline executives at Frankfurt airport, there was a sense of anticipation with everyone eager to see the reaction from the first paying passengers to have flown on the new Airbus A350-900. Draped in Qatar Airways livery and powered by the world’s most efficient large aero-engine, this was a moment the aviation world had been waiting for.

Two years on, and the Trent XWB has most definitely lived up to the hype. Since that initial flight from Doha to Frankfurt, the Trent XWB has powered 62 A350s into service and flown more than eight million passengers around the globe. Ten operators are currently benefiting from the Trent XWB’s outstanding efficiency with a further 12 airlines joining the fleet over the next 12 months.

The outstanding efficiency has also been matched by an impressive dispatch reliability of 99.9 per cent, meaning that if there’s a Trent XWB under the wing you can be confident of taking off on time. Rolls-Royce has launched an enhanced version of the Trent XWB, the world’s most efficient large aero-engine, powering the Airbus A350 XWB. The first customer is Singapore Airlines.

The Trent XWB-84 EP (Enhanced Performance) goes beyond the original Trent XWB-84 performance target levels, offering a fuel consumption improvement of 1 per cent, ensuring that the Trent XWB will remain the most efficient large engine in the marketplace into the next decade.

The Trent XWB-84 EP incorporates technologies from the higher thrust Trent XWB-97 engine, the Advance engine programme and other future technology research, with the first engine delivered in Q4 2019 to power a Singapore Airlines A350-900. The upgraded engines will also be offerable to other existing customers with deliveries after this date.

Eric Schulz, Rolls-Royce’s President for Civil Aerospace, said: “I’m proud that we are making the world’s best engine even better, and I am honoured that such a respected and valued customer as Singapore Airlines will be our first customer. I look forward to seeing this latest standard of engine deliver outstanding performance for Singapore Airlines for many years to come.”

Technology improvements on the Trent XWB-84 EP include: Improved turbine cooling and aerodynamics from the Trent XWB-97 and Advance programmes; Improved secondary air system and inter-stage sealing from the Trent XWB-97 programme; and Further optimisation of Trent XWB-84 turbine tip clearance control system based on recent improvements on other programmes.

Pratt & Whiney Banks on PurePower

Pratt & Whitney has invested over $10 billion and 20 years in perfecting the geared turbofan engine and it’s paying off. The PurePower PW1000G engine delivers game-changing reductions in fuel burn, environmental emissions, engine noise and operating costs. With more than 13,000 large commercial engines installed today, Pratt & Whitney provides dependable power to hundreds of airlines and operators every day. Its fleet of commercial engines has logged more than 1 billion hours of flight, powering the narrow- and widebody aircraft that fly both passengers and cargo around the world.

CFM Continues to Leap Forward

The LEAP-1A, which powers the Airbus A319neo, A320neo, and the A321neo aircraft, features some of the industry’s most advanced technologies, including 3D woven carbon fiber composite fan blades and fan case; a unique debris rejection system; fourth-generation threedimensional aerodynamic designs; the twin-annular, pre-swirl (TAPS) combustor featuring additively manufactured fuel nozzles; ceramics matrix composite shrouds in the high-pressure turbine; and titanium aluminide (Ti-Al) blades in the low-pressure turbine. The LEAP delivers a 15 per cent improvement in fuel consumption, compared to today’s best CFM56 engines, and maintains the same level of dispatch reliability and life-cycle maintenance costs.

The LEAP-1A which powers the Airbus A320neo has a 24,500-35,000 pounds thrust at altitude, while the LEAP-1B that powers the Boeing 737 MAX has a thrust of 23,000-28,000 pounds and the LEAP-1C which is on COMAC C919 has 27,980-30,000 pounds thrust.

LEAP-1A engines are a product of CFM International, a 50/50 joint company between GE and Safran Aircraft Engines and the world’s leading supplier of commercial aircraft engines. To date, the company has garnered orders and commitments for more than 11,500 LEAP engines, making it the fastest-selling engine in aviation history. The world’s top jet engine makers are indeed investing heavily in research and development efforts to rake in from the mega orders that are being placed globally by airlines.