Leap Years Ahead

CFM estimates that the LEAP can save an airline as much as $1.6 million in fuel costs per plane per year

In November this year, CFM International reported exceptional performance of the LEAP (Leading Edge Aviation Propulsion) engine in ground and flight tests, on course to its certification on the Airbus A320neo and Comac C919 in 2015. A month earlier, the engine took to the skies for the first time on a modified 747 flying test-bed at GE Aviation Flight Test Operations in Victorville, California, and had completed over 75 hours of flight testing.

“This engine has performed well beyond our expectation,” said Jean-Paul Ebanga, President and CEO of CFM. “The results we are achieving across the board are outstanding and reinforce not only the technology choices we have made but also the overwhelming acceptance it has garnered from airlines around the world. We couldn’t be happier with where this programme is today.”

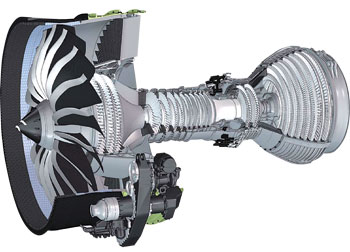

The LEAP incorporates technologies that CFM developed as part of the LEAP56 technology acquisition programme which CFM launched in 2005. The engine was officially launched as ‘LEAP-X’ on July 13, 2008. It is intended to be a successor to the CFM56-5B and CFM56-7B. The LEAP’s basic architecture includes a scaled up version of Safran’s low pressure turbine used on the GEnX engine. The LEAP uses composite materials, a blisk fan in the compressor, a second-generation twin annual pre-swirl combustor and a bypass ratio around 10-11.1. These technological advances are projected to produce 16 per cent lower fuel consumption.

CFM is currently executing the most extensive ground and flight test certification programme in its history. The total programme which encompasses all three LEAP engine variants include 28 ground and CFM flight test engines, along with a total of 32 flight test engines for Airbus, Boeing and Comac.

$1.6 MILLION SAVING IN FUEL COSTS PER PLANE PER YEAR

The foundation of the LEAP engine is heavily rooted in advanced aerodynamics, environmental and materials technology development programmes. It will provide double-digit improvements in fuel consumption and CO2 emissions compared to today’s best CFM engine, along with dramatic reductions in engine noise and emissions. All this technology brings with it CFM’s legendary reliability and low maintenance costs. CFM estimates that the LEAP can save an airline as much as $1.6 million in fuel costs per plane per year.

GROWING ORDERS

CFM has received more than $100 billion in orders (US list price) from airlines like United, AirAsia, American Airlines and easyJet. They will use them on single-aisle aircraft, the fastest growing market in commercial aviation. A recent Boeing study projected that plane manufacturers will deliver more 23,000 single-aisle planes over the next 20 years. That’s almost 70 per cent of all commercial plane deliveries estimated over the period.

LEAP engine is already the best-selling engine development in the history of civil aviation with over 7,800 orders and intentions of orders received as of October 31, 2014.

CFM, which is co-owned by General Electric and Safran, is on track to win safety approval for the first two versions of the engine in 2015. The LEAP engine is one of two power plants whose development has galvanised the aerospace industry in recent years as their much-improved fuel efficiency triggered a huge jump in plane sales and pushed anticipated production rates to record levels.

The new engine’s core will feature eight-stage compressor and single-stage turbine. LEAP-X will incorporate three-dimensional, woven resin transfer moulding (3-DW RTM) technology that dramatically reduces engine weight while providing a more durable blade as well as titanium-aluminide (Ti-Aluminide) lightweight alloy. The 3-DW RTM technology is expected to reduce the engine weight by 400 pounds and the composite fan blade count by 25 per cent.

There are three versions of the jet engine: the LEAP-1A for the new Airbus 320neo passenger jets, the LEAP-1B for Boeing’s 737MAX aircraft, and the LEAP-1C for China’s Comac C919 planes. The CFM LEAP-1B will be the exclusive power-plant for the Boeing 737 MAX family of single-aisle aircraft (737 MAX-7, 737 MAX-8, 737 MAX-9). This engine has been optimised to provide the 737 MAX the best possible fuel efficiency while maintaining the reliability and maintenance cost legacy of the CFM56 family.

TESTING SCHEDULE CONTINUES

“The LEAP engine certification programme is the most extensive development and certification programme in our history,” said Chaker Chahrour, Executive Vice President of CFM. “The tests we are performing are designed to push the limits of this engine, in addition to certifying it for commercial service.”

Paul Ebanga said that ‘greener engines’ is a subject which has been part of the conversation at CFM International since the inception of the company. From the very beginning designing more environmentally responsible engines was part of the most important objectives of our company. This matter goes far beyond CFM or any other manufacturer individually. The environmental challenge is not about market share, it is about what the future we leave our children and what contribution we are able to make towards achieving that goal.

Paul Ebanga said when the CFM56 was introduced early in the 1980s, “we were able to improve CO2 emissions by 25 per cent versus the previous generation of engines. Over the next 30 years of production, the CFM56 has been continuously improved and refined. It continues to define today the industry standard in terms of the lowest emission levels of an engine in the single-aisle market. With the CFM56 again, we have been at the forefront with Airbus to demonstrate the viability of the biofuel solution.”

ENVIRONMENTAL CONCERNS

Paul Ebanga said that environmental concern is part of CFM’s DNA. “We have in the past and we will continue in the future to invest in technology to put more efficient and more ecofriendly products on the market. We can be even a little bit more granular in order to better understand what this means. Let us do simple math. In 2013, 705 million tonnes of CO2 were produced by all the aircraft flying in the world. That translates to roughly 27,200 tonnes of CO2 per aircraft and per year. If an aged aircraft is replaced with a brand-new one, powered by our advanced LEAP engine, we could achieve between 15 and 40 per cent reduction in fuel burn and CO2 emissions, depending on the age of the engines being replaced. If we take a 25 per cent improvement as an average, it means, for each older aircraft replaced, we are going to eliminate around 6,800 tonnes of CO2 per year. That is the bottom line result of contribution of the engine industry.”

He further said: “From a broader industry perspective, we are very pleased by the current momentum around sustainable aviation and are proud to be part of it. We are in full support of the initiative by the Air Transport Action Group (ATAG). The ATAG is a fully respected not-for-profit association that represents all the sectors of the air transport industry and which aims to coordinate industry positions related to strategic environmental and infrastructure issues. From that perspective, we are committed to meeting our commitment to help fulfil the 2020 and 2050 objectives for CO2 emissions reductions, as well as to share our expertise in achieving results through global partnership.”

At the moment the aviation community is facing a a major challenge – that of reducing fuel consumption, primarily due to rising fuel prices and environmental concerns. In 2012, US commercial ATF carriers burned 10.6 billion gallons of jet fuel costing $31.6 billion. The aviation industry, specifically, engine manufacturers are working on technologies to improve fuel efficiency and CFM is in the forefront of such technological development.