We are not talking

We are acting

We are doing

The CFM56 defines the industry standard in terms of the lowest emissions level of an engine in the single-aisle market

“Greener engines” is a subject which has been part of the conversation at CFM International since the inception of the company. From the very beginning designing more environmentally responsible engines was part of the most important objectives of our company. This matter goes far beyond CFM or any other manufacturer individually. The environmental challenge is not about market share, it is about what the future we leave our children and what contribution we are able to make towards achieving that goal.

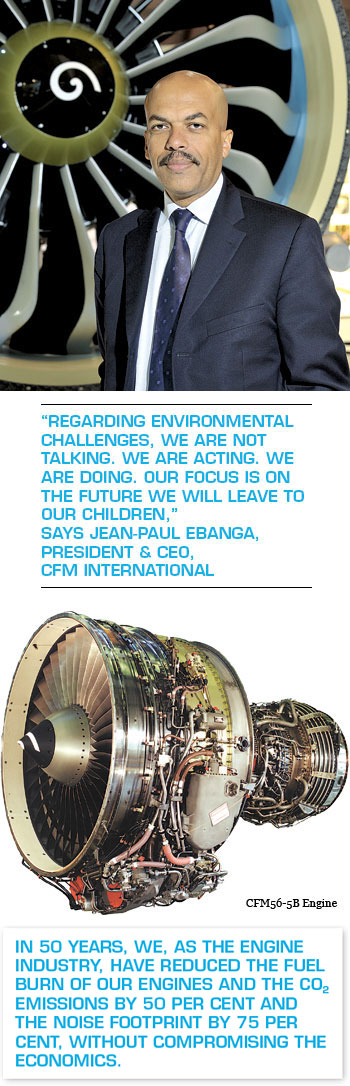

In that perspective, our industry has done a phenomenal job. In 50 years, we, as the engine industry, have reduced the fuel burn of our engines and the CO2 emissions by 50 per cent (70 per cent engines plus aircraft) and the noise footprint by 75 per cent, without compromising the economics.

To have an appreciation for the CFM commitment on environmental matters, let me share few figures. When the CFM56 was introduced early in the 1980s, we were able to improve CO2 emissions by 25 per cent versus the previous generation of engines. Over the next 30 years of production, the CFM56 has been continuously improved and refined. It continues to define today the industry standard in terms of the lowest emissions level of an engine in the single-aisle market. With the CFM56 again, we have been at the forefront with Airbus to demonstrate the viability of the biofuel solution.

And the trend continues. In 2008, CFM decided to engage in an unprecedented level of investment in order to develop the next generation of engines, the LEAP, which will bring another amazing step change in terms of environmentally-friendly engines. The LEAP engine will reduce fuel burn and the associated CO2 emission by 15 per cent compared to today’s best CFM56 engine, which is already the best in the industry.

The point is that environmental concern is part of our DNA. We have in the past and we will continue in the future to invest in technology to put more efficient and more eco-friendly products on the market.

We can be even a little bit more granular in order to better understand what this means. Let us do simple math. In 2013, 705 million tonnes of CO2 were produced by the all aircraft flying in the world. That translates to roughly 27,200 tonnes of CO2 per aircraft and per year. If an aged aircraft is replaced with a brand-new one, powered by our advanced LEAP engine, we could achieve between 15 and 40 per cent reduction in fuel burn and CO2 emissions, depending on the age of the engines being replaced. If we take a 25 per cent improvement as an average, it means, for each older aircraft replaced, we are going to eliminate around 6,800 tonnes of CO2 per year. That is the bottom line result of contribution of the engine industry.

Regarding environmental challenges, we are not talking. We are acting. We are doing. Our focus is on the future we will leave to our children.

From a broader industry perspective, we are very pleased by the current momentum around sustainable aviation and are proud to be part of it. We are in full support of the initiative by the Air Transport Action Group (ATAG). The ATAG is a fully respected not-for-profit association that represents all the sectors of the Air Transport industry and which aims to coordinate industry positions related to strategic environmental and infrastructure issues. From that perspective, we are committed to meeting our commitment to help fulfill the 2020 and 2050 objectives for CO2 emissions reductions, as well as to share our expertise in achieving results through global partnership.