Rich Rolls-Royce Heritage

The collection in Derby is housed over two sites and contains over 200 engines

At Derby in the United Kingdom, the Rolls-Royce facility is a destination in itself. The individual who drove the visiting Indian journalists to the facility explained how it had become part of their lives, not just providing employment but also contibuting to economic development. Developing the best of engines has been the forte of Rolls-Royce and it has a historic legacy. The visiting journalists were taken to the Heritage Centre which gives an insight into engine development, specifically by Rolls-Royce. The Rolls-Royce Heritage Trust was formed in 1981 to promote and preserve the history and engineering excellence of the company. There are five branches which serve the historical interests of the ancestor companies that, over the years, were assimilated to create the present-day Rolls-Royce.

The Derby & Hucknall branch and the Scottish branch are concerned primarily with the heritage of Rolls-Royce Limited. The Bristol branch covers the products and history of the early Bristol and Bristol Siddeley companies as well as the famous names of deHavilland, Blackburn and Napier. The Coventry branch is located both at Ansty and Derby and is the authority on Armstrong Siddeley and its predecessors. The Indianapolis Branch in the United States is dedicated to the achievements of the Allison Engine Company. While the majority of exhibits are aero-engine related, there are an increasing proportion of items relevant to marine, energy and land vehicle engines reflecting the historical importance and current growth of these businesses in Rolls-Royce.

The Trust publishes a magazine twice a year for its members titled The Journal of the Rolls-Royce Heritage Trust. Books are also published at regular intervals and specialise in the histories of the products of Rolls-Royce and its ancestor companies ranging from aero-engines, motor cars, premises and people. The Trust has also recently started to produce DVD titles. The Derby & Hucknall, Bristol and Coventry branches have workshop facilities where engines and related artefacts are preserved and restored for exhibition. A wide variety of these engines, as well as other exhibits, are on permanent display.

The collection in Derby is housed over two sites and contains over 200 engines. The exhibits chronicling not only the history of Rolls-Royce, but also that of many of companies which have become part of the Rolls-Royce family. The majority of the exhibits relate to aero-engines but there are also vehicle, marine as well as industrial diesel and gas turbine engines and a display of rockets. Together with the Coventry collection and several engines from the Bristol collection, the Derby collection is a comprehensive history of propulsion on land, on the sea and in the air.

Eagle to Trent, Long Journey

The Rolls-Royce Heritage Centre contains a selection of Rolls-Royce aero-engines and parts from the formation of the company to the present day, including the Merlin and RB211 engines. The Rolls-Royce company didn’t start with aeroengines, it all began with cars. After cars the early aero-engines are displayed here—including the record-breaking Eagle, designed by Henry Royce in 1914 response to the nation’s needs at the start of World War I. Then comes the famous Merlin engine which powered, among other aircraft, the Spitfire and the Hawker Hurricane.

The company developed the first jet engine with Frank Whittle’s distinctive-looking jet, the Welland. Then there is the Rolls-Royce Avon-powered Canberra and, the Conway engine, which became the first turbofan to enter airline service on the Boeing 707. Rolls-Royce’s original ‘big daddy’—the RB211—built in the 1960s for wide-bodied airliners, is majestic in its place. It was also the engine that led to the company being taken into state ownership in 1971 due to the huge development costs—the Rolls-Royce ‘crash’. In the 1980s, Rolls-Royce also entered the marine power market. And not to forget, there is the huge Trent 900 engine, which powers the double-decker Airbus A380, and the Pegasus, famous for powering the Harrier Jump Jet.

Trent Makes a Splash

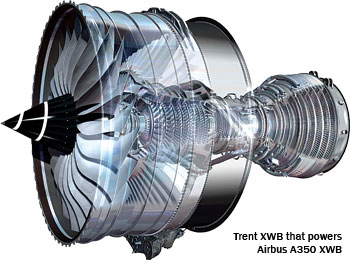

Giving a perspective of engine developments, Iain Dudley, Product Marketing Manager, Rolls-Royce, said that in 1995, when Trent 700 entered into service, the price of aviation turbine fuel was 60 US cents per gallon and now it has shot up to $3 per gallon. Simply put, it meant that fuel prices would keep going up and it was for the engines to optimally perform to offset the rising fuel costs. A tall order indeed, but engine manufacturers are seized of the matter and considerable development is taking place. Rolls-Royce has seven engines in its Trent family – the XWB, 1000, 700, 7000, 800, 900 and 500. It is the engine of choice for this generation and the next, powering about 50 per cent of the next-generation wide-body aircraft. The projected deliveries are 4,000 up to 2023 as against the 1,600 delivered in the last decade. The Trent XWB has over 700 firm aircraft with 39 customers and some of them include Etihad Airways, Qatar Airways, Thai Airways, Air France KLM, Singapore Airlines, Azul, Japan Airlines and Sri Lankan Airlines.

This is the outcome of painstaking effort of the engineers at Rolls-Royce. The Trent XWB has undergone four years of testing across the globe, starting with Derby; Glacier, Manitoba; Edwards Air Force Base, California; Stennis, Mississippi; INTA, Madrid; and Dahlewitz. Till date, it has done over 7,116 hours of testing. The climatic engine tests have been successfully completed at Eglin Air Force Base in Florida with engine runs at +45 to -40 degrees Celsius. The hot weather tests have been carried out at Al Ain in the United Arab Emirates.

Giving features of the Trent XWB engine, he said, that it had high-flow fan system enabled with inflected annulus; larger core to increase flow; increased mechanical capability for 97,000 lbs thrust; maintain nacelle aerolines as 84 k engine; and high capability turbines. The fan and the core have been optimised for 97,000 lbs thrust.

The design and technology enablers are increased flow fan system; impingement effusion combustor; adaptive cooling system; advanced tip cooling; high temperature materials and coatings as well as shroudless blade system. The Trent 1000 is designed and optimised for the Boeing 787 family. It has been selected by about half of 787 customers. The Trent 1000 offers the best lifetime fuel-burn performance and is fitted on the Boeing 787-9 Dreamliner. The Trent 1000 powers 51 aircraft with six operators and one lessor.

The Trent 700, in its 19 years of service so far, is fitted on 605 aircraft, the largest in-service fleet of RB211 and Trent engines. It has completed 28 million flying hours with a dispatch reliability of 99.9 per cent. The Trent 700 Regional is perfectly matched to the A330 Regional. The features are optimised thrust, reduced maintenance cost, inter-changeable, is easily upgraded and it is the best value on the A330.

The evolution to the Trent 7000 has its foundations in the experience of Trent 700, the architecture of the Trent 1000-TEN and the technology of the XWB. The Trent 7000 matches the A330neo. From the Trent 700, the 7000 has double the bypass ratio, 10 per cent better specific fuel consumption and 10 db less half the noise.

The Trent 900, which entered service in 2007, is fitted on 67 aircraft and has clocked 3.27 million flying hours with again a dispatch reliability of 99.9 per cent. It is an engine of choice with British Airways, Qantas, Singapore Airlines, Lufthansa, Virgin Atlantic, China Southern, Thai, Asiana Airlines, VIP and Skymark, with deliveries for the last two years. It is the engine of choice on the A380.