Pratt & Whitney GTF Family continues its way up

The GTF engine is in a league of its own. The first in a new era of commercial jet engines, the GTF is built with an architecture that is superior by design with an unmatched runway for growth

Pratt and Whitney, a division of Raytheon Technologies Corp. announced on December 18, 2020 that the Geared Turbofan (GTF) engines powering the A320neo family have achieved a world-class engine dispatch reliability rate of 99.98 per cent. “The GTF engine powers more than 900 aircraft across nearly 50 airlines and three aircraft families: Airbus A320neo, Airbus A220 and Embraer E-Jets E2. GTF engines have saved more than 400 million gallons of fuel and over 3.8 million metric tonnes of carbon emissions since they entered service in 2016,” the manufacturer stated.

Thanks to upgrades completed in close coordination with our customers in 2020, GTF engines for the A320neo family are now delivering industry-leading reliability. When you combine this with our best-in-class fuel efficiency and low carbon emissions, it’s easy to see why GTF-powered fleets have seen high utilisation as the industry begins to recover,” said Carroll Lane, President of Commercial Engines at Pratt & Whitney.

The manufacturer also added that the fleet has achieved an exceptional level of operational performance: A320neo family aircraft with GTF engines have averaged more flights and more hours per day than comparable aircraft. “The GTF-powered A320neo family is currently operating at about 90 per cent of its pre-pandemic utilisation levels. The A220, E190-E2 and E195-E2 have also proven their value with our customers, with airlines depending on them for the right mix of capacity, range and economics. These aircraft have been operating at about 80 per cent of pre-COVID utilisation throughout much of the crisis,” added Lane.

“Thanks to upgrades completed in close coordination with our customers in 2020, GTF engines for the A320neo family are now delivering industry-leading reliability. When you combine this with our best-in-class fuel efficiency and low carbon emissions, it’s easy to see why GTF-powered fleets have seen high utilisation as the industry begins to recover,” said Carroll Lane, president of Commercial Engines at Pratt & Whitney.

Pratt & Whitney (P&W) pointed out that it accomplished this by taking advantage of the downtime afforded by the crisis, during which the company developed “quick turn” shop visit capability to incorporate product upgrades across a rapidly growing service network. This year, the company also announced that four new facilities would join the GTF MRO network: Aircraft Maintenance and Engineering Corporation (Ameco) Beijing, MTU Maintenance Zhuhai, OGMA in Portugal and China Airlines in Taiwan. Air India Engineering Services Limited (AIESL) was also announced as a provider of maintenance services in support of GTF operators in India and the surrounding region. Additionally, two network facilities completed their first engine overhauls: Delta TechOps in the U.S. and EME AERO in Poland.

Despite the pandemic hitting the world, P&W welcomed new customers to the growing GTF family this year itself including Aegean Airlines, China Express Airlines, Middle East Airlines and SWISS. Each of these took delivery of their first GTF-powered A320neo family aircraft, while Air Canada entered service with its first A220 aircraft and Juneyao Air began operations with its first A320neo aircraft.

P&W also highlighted that since entering service in early 2016, the GTF engine family has delivered on its promised ability to reduce fuel burn and carbon emissions by up to 20 per cent, and to dramatically reduce regulated emissions and noise footprint.

Among other accomplishments, before this year like no other comes to an end, P&W is adding feather to its hat. The manufacturer’s GTF engines, which power Airbus A320 NEO family planes being operated by budget carriers IndiGo and GoAir have crossed two million flight hours in India, the US engine maker reported recently. There are over 180 Airbus planes with Pratt & Whitney (P&W) GTF engines in India. “Our customers IndiGo and GoAir were early adopters of the revolutionary GTF engine, and we are happy to say that these engines have crossed two million flight hours in India,” Pratt & Whitney President and Country Head for India Ashmita Sethi said in a release. “With more than 180 GTFpowered aircraft in India and an extraordinary engine dispatch reliability rate of 99.98 per cent, our customers are recognising the superior fuel efficiency that GTF engines deliver. Since cost savings are especially important in the current environment, we’ve seen airlines prioritise operating their GTF-powered aircraft before any others,” she added.

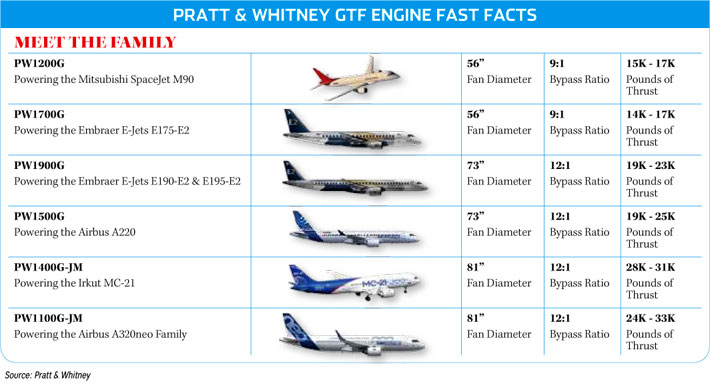

The GTF engine, with its revolutionary geared fan technology, is transforming aviation by delivering game-changing economic and environmental performance. The GTF engine powers five aircraft platforms, with the Airbus A220, the Airbus A320neo family and Embraer E190-E2 already in commercial service. The Mitsubishi Regional Jet (MRJ) and Irkut MC-21 are currently undergoing flight testing. The GTF engine has met all performance specifications since the start of entry into service. For example, the GTF-powered A320neo has achieved a 16 per cent reduction in fuel consumption, a 75 per cent reduction in noise footprint and a 50 per cent reduction in nitrogen oxide emissions.

The GTF engine’s fan-drive gear system is just one component of this next-generation engine. The Pratt & Whitney GTF engine also incorporates advances in aerodynamics, lightweight materials and other major technology improvements in the highpressure spool, low-pressure turbine, combustor, controls, engine health monitoring and more.

With a strong backlog of more than 8,000 firm and option engines on order with over 80 customers, the GTF offers approximate savings of 100 gallons of fuel per flight hour and reduction in C02 of 1 metric ton per flight hour.

Pratt & Whitney GTF engines will help drive more efficient, sustainable air travel, enabling airlines to open new routes and fly more people farther, with less fuel – and much lower noise. Operators have the ability to create options for routes that didn’t exist before and make point to point destinations more available to the flying public. These benefits result in quieter communities, quieter flights, cleaner air and economic development.

The pioneering technology of the GTF allows for further evolution and performance enhancements in the future. Being at the very early stages of this new technology, we see a tremendous runway for further efficiency gains and new aircraft applications.