Composites to Reduce Weight of Aero Engines

The jet engine is the most complex element of an aircraft and one of the most complex human-made products ever developed, housing thousands of individual components and ultimately determining fuel efficiency for aircraft

At present, the single-most important aspect of aircraft operating cost is fuel which represents 33 to 40 per cent of global airline expenses and even at somewhat moderated cost inflation could soon climb to 50 per cent or more. Aero engine manufacturers have replaced metal with composites to mitigate the weight increase of the engines. Throughout the 1980s and 1990s, the application of composites in aircraft engines was relatively limited. More than half of the total composite volume was directly associated with nacelle components, such as thrust reversers, acoustic liners, cascades, blocker doors, radial drive fairings and cowlings. On some models, aramid fibres (often in the form of dry-fibre belts) were used to reinforce aluminium fan cases. Composite nose cones, a variety of air ducts and engine air-oil seals were fairly common as well. A modest attempt in aero engines weight reduction!

When GE’s GE90 engine entered service in 1995, it applied many more advanced materials and Resin Transfer Moulding (RTM) processing to introduce a number of new composite components, most notably, large fan blades made from hundreds of plies of intermediate-modulus carbon fibre prepreg. Since then, composite blades, fan containment cases, bypass ducts, stator vanes and a host of components and brackets have become common not only in commercial jets but also in business and military aircraft.

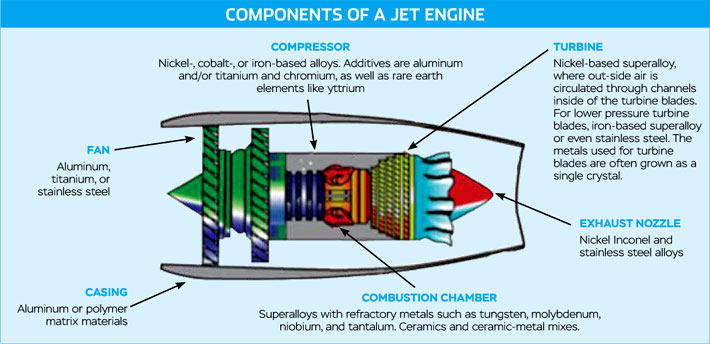

The jet engine is the most complex element of an aircraft and one of the most complex human-made products ever developed, housing thousands of individual components and ultimately determining fuel efficiency for aircraft. Traditionally, certain materials have been used specifically for different parts of the jet engine as illustrated above.

COMPOSITES TECHNOLOGY

Materials technology is of fundamental importance to the gas turbine engine. The ultimate efficiency of the engine is limited by operating temperature and, consequently, it requires materials with high temperature capability. The persistent drive to reduce emissions is compounding this need. Engine weight is another important factor, impacting on fuel consumption and military aircraft agility, thus stimulating the demand for low-density materials. The fuel consumption of large aircraft could be reduced by one per cent if the jet engine weight is lowered by approximately 68 kg. In addition, as weight reduction of the jet engine would result in reduced airframe structural strength for supporting the engine, weight reduction of airframes can also be expected.

However, considering that the melting point of current super alloys is around 1,850°C, the challenge becomes finding materials that will withstand hotter temperatures. The advent of leanburn engines, with temperature potentials as high as 2,100°C, has pushed the demand for these new materials. To achieve higher thrust, higher operating temperatures must be realised and for higher efficiency, engines must be made significantly lighter without loss of thrust. In either case, new families of materials need to be developed that have higher melting points and greater intrinsic strength.

Composites are any material system consisting of two or more discrete materials that collectively provide properties that are not exhibited by any of the constituent materials in isolation and most likely provide some form of performance improvement. Composites provide many benefits over traditional materials including better strength to weight ratio, improved durability, added functionality and more freedom in design configurations. Composite materials are typically formed of a fibrous reinforcement such as carbon or glass fibre, which provide strength and stiffness, embedded in a matrix material to provide the overall shape, support and toughness of the material.

WHY USE COMPOSITES?

The two major interrelated drivers for the application of Ceramic and Metal Matrix Composite (CMC and MMC), Fibre-Reinforced Polymers (FRPs) and Polymer Matrix Composites (PMCs) in engines have been weight reduction and performance improvement. MMC compressor drums have the potential for 80 per cent weight saving over a conventional disc and blade assembly and PMC components typically provide 20 to 30 per cent weight saving. The primary advantage of CMCs in addition to weight benefits is the ability to operate uncooled at temperatures beyond the reach of metals. Cycle efficiency improvements, from reducing cooling air to turbine aerofoils and seals, lead to significant specific fuel consumption benefits.

The single-most important aspect of aircraft operating cost is fuel which represents 33 to 40 per cent of global airline expenses

In today’s fiercely competitive aero engine market, the primary product discriminators are cost-driven. Typical cost savings of 20 to 30 per cent delivered by PMCs in replacing incumbent metal parts, therefore, provide added incentive for wider application of these materials. With these impressive advantages on offer, it may seem difficult to understand why composite materials do not dominate the latest civil and military engines.

COMPOSITES CANVAS IN AERO ENGINES

The increasing production rate of composite-rich fighter aircraft such as the F-35 is likely to give an impetus to the demand for high-temperature composites in the industry. In addition to using composites for extremely high-tech carbon fibre fan blades, jet engine manufacturers are also incorporating CMC parts that can withstand extremely high temperatures in the hot sections. The use of CMC parts enables weight reduction for engines and allows them to run at much higher temperatures, improving performance and efficiency. These ceramic matrix composites have taken the market in an aggressive manner. For example, while 50 per cent of the Boeing 787 Dreamliner’s weight is made up of composites, Airbus, with its new A350 XWB, surpasses this with 53 per cent composite content.

To achieve an excellent strength-to-weight ratio while pushing the service temperatures into the range from 600°F to 1,000°F in newer jet engines and fifth-generation fighter aircrafts has created an upsurge in demand for composite materials. Lockheed Martin’s F-35, which has incorporated high-temperature composites, is among the best-selling fifth-generation aircraft. About 35 per cent of the aircraft is made of composites, approximately 50 per cent of which are high-temperature composites.

Rolls-Royce, which is one of the biggest aircraft engine manufacturers, has been working on SiC CMCs that can endure high temperatures of 1,900°C. These are also two-thirds lighter than traditional nickel-based alloys. Commercially, SiC fibres are developed by a technology owned solely by Nippon Carbon and Ube Industries.

General Electric, the largest jet engine maker has collaborated with Nippon Carbon to manufacture its CMC material for jet engines, which is projected to improve fuel efficiency by two per cent. GE Aviation’s two-plant manufacturing site in Asheville, North Carolina, is among the first operations to mass produce CMC components for commercial jet engines. GE9X engine is the most fuel-efficient jet engine the company has ever produced on a per-pounds-of-thrust basis. The GE9X was developed on the foundations of the GE90 which was developed back in the early 1990s.The GE9X is designed to achieve an overall pressure ratio of 60:1 and bypass ratio of approximately 10:1, and has CMC material in the combustor and turbine.

A320neo family aircraft and 737 MAX jets leap engines that power these two models and the MC-21 aircraft have composite structures which include 3-D woven carbon fibre composite fan blades and fan case. Also, Ceramic Matrix Composites (CMC) are being used to build the turbine shrouds of the engine. A320-200neos to the larger A321-200neo aircraft Leap Engines used in the aircraft uses a higher volume of composites compared to its predecessors.

About 35 per cent of the aircraft is made of composites, approximately 50 per cent of which are high-temperature composites

Even the engine of the new C919 aircraft from China fitted with the Leap engine, has the engine’s nacelle made of about 60 per cent composite materials. India newest induction, the Dassault Rafale jets, are powered by the M88 engines have the nacelles and nozzles made using thermos-structural composites from Safran Ceramics.

DRIVING AERO ENGINE COMPOSITES MANUFACTURE

In the engine manufacturers, CFM International and GE Aviation are generating the highest demand for the aero-engine composites, whereas other manufacturers such as Rolls-Royce and Pratt & Whitney are expected to increase the volume of composite usage in their engine models in the years to come. Over the years, engine manufacturers have developed significant in-house composites manufacturing capacities. For instance, GE has its own composites manufacturing facilities in addition to various joint ventures (like Nexcelle with Safran). This trend may affect the market revenues of the Composite Suppliers for the engine OEMs. The usage of the composites is increasing in the aircraft. Along with this, the increase in overall engine production rates means a considerable growth impetus for the aero engine composite part manufacturers and their respective supply chains. Simultaneously, composite material suppliers will need to expand their raw materials output to stay in the competition which is currently higher than ever before in the market.

COMPOSITES TECHNOLOGY TRAJECTORY

The key opportunities in the technology trajectory of composites in the use of Aero Engines in the near future are:

- Lightweight composite fan and rotor/propeller systems including containment elements.

- Ultra-High Bypass Ratio Engines (UHBR) with larger diameter composite fan systems and slim line, lightweight nacelle structures.

- Ceramic Matrix Composites for turbine blades and other components.

The use of composites in Aero Engines is being researched very aggressively by industry and academia. The other opportunities in the medium to long term, I foresee are:

- Advanced lightweight transmission, compressors, turbines and external systems.

- Utilising advanced composite materials with high temperature capabilities.

- High temp Ceramic Matrix Composites for hot static components.

- Metal Matrix Composite rotating components.

- Active helicopter composite blades with morphing capability.

- Advanced high-strength, lightweight composite propellers.

- Hybrid turbo-electric and distributed propulsion systems utilizing lightweight composite structures and elements.

- More electric propulsion systems with associated lightweight composite supporting structures.