Engines for Regional Jets

As far as transportation is concerned, the focus is beginning to shift from fossil fuels to Electric Power or alternate fuel using Hydrogen Fuel Cells

As the name Regional Jets suggests, these airplanes are in a different class from others. Therefore, it is necessary to see the various different classes and categories of airliners. Airliners get classified based on passenger carrying capacity, All Up Weight (AUW), number of engines, number of aisles and their flying range. There are various combinations of the criteria listed above and hence there are a large number of categories of airliners.

DEVELOPMENT

Typically, a Regional Jet is a small aircraft meant for operating regional flights. Its definition has undergone a change through a process of evolution. Initially, it was classified as a class that could carry 66 to 100 passengers. These days Regional Jets typically carry between 66 to 150 passengers. That puts most of these aircraft in the sub 40-tonne AUW category. Incidentally, India offers landing parking charges waiver for aircraft below 40-tonne AUW operating under the UDAN banner.

Regional Jets usually have less than 150 seats and are typically produced by aircraft manufacturers that specialise in making small aircraft. For example, neither of the two biggest airliner manufacturers, namely Airbus and Boeing, produce Regional Jets. Instead, these are produced by Embraer, Bombardier, Sukhoi, Antonov and COMAC. A comparative list of Regional Jets, currently in operation, is placed below.

- Antonov An-148 (2009– 68–99 seats)

- Bombardier CRJ700 series (2001– 66–104 seats)

- Comac ARJ21 (2016– 78–105 seats)

- Sukhoi Superjet 100 (2011– 87–108 seats)

- Embraer E-Jet and E2 Family (2004 - 66-124 seats)

The Regional Jets are gradually making inroads into a domain that was reserved for turboprops. Regional Jets do cruise at flight levels that the large airliners do and about the same Mach Number. To enable these airplanes to cruise at high altitudes and at speeds close to those of large airliners, their engines have to be in the 15,000 to 20,000 lbf thrust class.

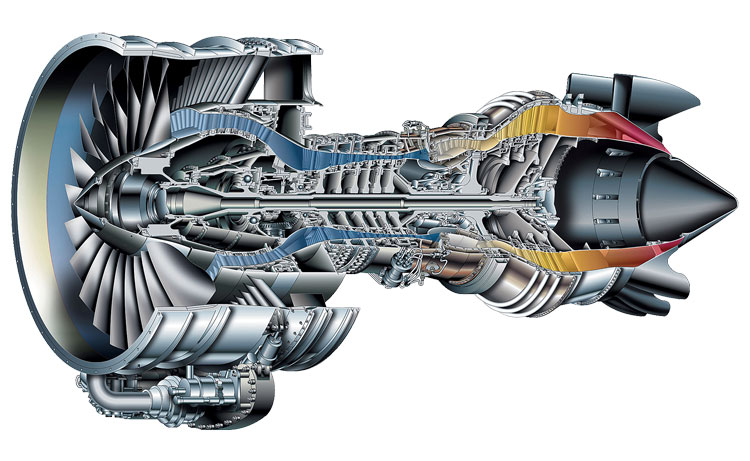

The amazing aspect is that the engine technology has progressed in leaps and bounds and even the engines which power the Regional Jets are turbofan engines that are the order of the day. All revenue generating airplanes are powered by turbofan engines. The fan technology has been refined to an extent that was unbelievable a few years ago. As a result, there is a large range of fuel efficient, reliable and rugged turbofan engines from the very small to large.

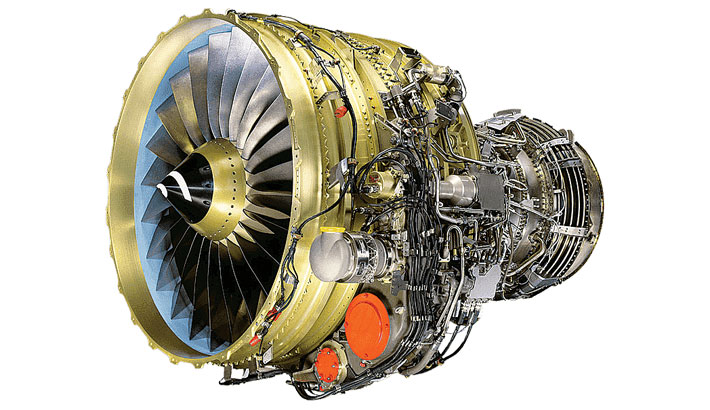

Unlike the airframe manufactures, wherein the two major manufacturers, Airbus and Boeing do not touch Regional Jets, the aero engine manufacturers are different. All engine manufacturers design and manufacture engines of all thrust ratings. There are quite a few big manufacturers who have entered into joint ventures across continents and are producing superb engines. The four major players in the Western world are Rolls-Royce, Pratt & Whitney, General Electric and SAFRAN (erstwhile SNECMA).

Some of these manufacturers have entered into joint ventures amongst themselves. For example, General Electric with SNECMA jointly produced an all-time winner, the CFM-56. International Aero Engines (IAE) is a multinational corporation registered in Zurich, comprising Pratt & Whitney, Rolls-Royce, Japanese Aero Engine Corporation, MTU Aero Engines of Germany, and Fiat Avio of Italy. This corporation developed the well known V2500 engine now in use on a large number of A320s. Others have entered into ventures with Russian, Chinese, German and Japanese companies to produce a whole host of engines.

Today, the aero engines for civilian applications can, generally, be classified into three categories:

- Large Fan Engines for Wide Body airplanes. 50,000 lb thrust and above.

- Medium-thrust Engines 25,000 – 35,000 lb thrust for the single - aisle airliners of the Airbus 320 and Boeing 737 families.

- Small Fan Engines 15,000 – 20,000 lb thrust for the Regional Jets.

It is the small turbofan engines that power the Regional Jets which is of interest to us. There are a host of engines that are in the market for the Regional Jets. Most surprisingly, they are a product of a large number of joint ventures. Given below is a list of comparable engines available for the Regional Jets:

- PowerJet SaM146

- Progress D-436

- General Electric CF34

- Pratt & Whitney PW6000

- Rolls-Royce BR700

PowerJet SaM146

This is a turbofan engine produced by the PowerJet corporation which is a joint venture between Snecma of France and NPO Saturn of Russia. Developing 15,000–18,000 lb of thrust, the SaM146 is used on the Sukhoi Superjet 100. Snecma is in charge of the core engine, control system (FADEC), transmissions (accessory gearbox, transfer gearbox), overall engine integration and flight testing. NPO Saturn is responsible for the components in the low pressure section and engine installation on the Sukhoi Superjet 100 Regional Jet and ground testing.

Progress D-436

This is a three-shaft, high by-pass turbofan engine developed by the Ukrainian company Ivchenko-Progress. It was developed in the 1980s for the late versions of the Yak-42 and the An-72. The engine first ran in 1985, and was subsequently certified in 1987. Several variants have been developed and are currently in service.

General Electric CF34

This is a civilian high-bypass turbofan developed by GE Aircraft Engines from its TF34 military engine. The CF34 is used on a number of business and Regional Jets including the Bombardier CRJ series, the Embraer E-Jets and the Comac ARJ21. In 2012, there were 5,600 engines in service. The original engine contained a single stage fan driven by a four-stage Low Pressure (LP) turbine, supercharging a 14-stage HP compressor driven by a two-stage High Pressure (HP) turbine. Later, higher thrust versions of the CF34 featured an advanced technology core, with only ten HP compressor stages. Latest variants, the 10A and 10E, were derived from the CFM56 engine family and have a radically different HP spool, containing a nine-stage compressor driven by a single-stage turbine. The LP spool has three-core booster stages behind the fan. Static thrust is 18,500 lbf for the -10E variant.

Pratt & Whitney PW6000

This was designed as the engine with minimum complexity to significantly reduce maintenance cost through weight and fuel consumption savings. However, tests revealed that the initial five-stage HP compressor-based design did not meet the fuel burn performance. To address the problem, Pratt & Whitney re-certified an updated design utilising a six-stage HP compressor designed by MTU Aero Engines in order to achieve the performance. The German company manufactures the high-pressure compressor and the low-pressure turbine. The engine made its first flight on August 21, 2000 on a test aircraft. The engine final assembly line is located at MTU Aero Engines in Hanover, Germany.

Rolls-Royce BR700

This family of turbofan engines powers Regional Jets and corporate jets. It was developed by BMW and Rolls-Royce through the joint venture BMW Rolls-Royce AeroEngines GmbH, established in 1990. The BR710 first ran in 1995. It is manufactured in Dahlewitz, Germany. Rolls-Royce took full control of the company in 2000, which is now known as Rolls-Royce Deutschland. The BR710 is a twin-shaft turbofan that entered service on the Gulfstream V in 1997 and the Bombardier Global Express in 1998. This version has also been selected to power the Gulfstream G550. In May 2017, the 3,200 engines in service reached ten million flying hours.

Electric powered airplanes are facing development challenges based on the battery weight and associated problems

Post 1995, the divide between the Western world and Russia/China in the domain of civil aero engines has broken down. There are joint ventures between French and Russian manufacturers and American engines are standard fit on Chinese airplanes. In short, manufacturers are looking globally for the best suited product for the project.

A study of the data of five Regional Jets engines will reveal that they are all around the 15,000 lbf to 20,000 lbf thrust, roughly of similar dimensions, thrust to weight ratio, bypass ratio and pressure ratio. The most amazing part of the leap in engine technology is the reliability. Engines do not come off the pylon mounts for up to 14,000 hours.

The civil aviation industry was booming till the onset of the COVID-19 pandemic. However, this too shall pass and in about three years, the industry will recover its original trajectory.

SHIFTING FOCUS

As far as transportation is concerned, the focus is beginning to shift from fossil fuels to Electric Power or alternate fuel using Hydrogen Fuel Cells. Apart from ground vehicles, airplanes are also being tried and tested with electric power and alternate fuels. Airplanes are at the moment in the very basic stage as far as electric powered propulsion is concerned. Electric powered airplanes are facing development challenges based on the battery weight and associated problems. Battery technology is simply not moving fast enough. This is where alternate fuels in airplanes is gathering momentum. Airbus has started a project aimed at zero emission called “ZEROe” and plans to have a passenger airplane in the air as early as 2030. The Airbus ZEROe concept illustration is shown below.

Source: Airbus

As can be seen, the concept is to have turboprop class airplanes carry up to 100 passengers over 1,000 nautical miles, while turbofan airplanes capable of up to 200 passengers in excess of 2,000 nautical miles. The boldest concept, however, is Blended-Wing Body airplane.

The way they are working on the concept is remarkable and barring some major hold-up, they should have a passenger aircraft operating a revenue flight by 2030. That would end the dependence on fossil fuels.

At present, development work is on in full swing on all three classes of aero engines - the big, medium and Regional Jet class. The results, in terms of fuel efficiency, are unbelievable. The reliability of turbine engines has been established beyond doubt. The era of gas guzzling engines is not over, but the end is near. There is light at the end of the tunnel as far as alternate fuels and low/zero emission engines are concerned. These are interesting times, and we just might soon have the privilege to fly transcontinental on a ZEROe airplane.